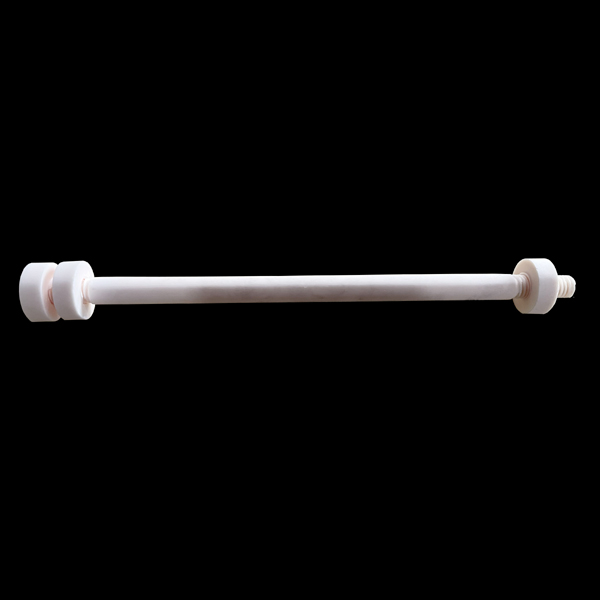

In a breakthrough development in the materials science industry, high-purity alumina threaded ceramic rods, with their excellent strength and durability, are expected to completely change various industries. This innovative product is made of advanced 99.3 alumina material, designed to withstand extreme temperatures and harsh conditions, making it an ideal choice for high-performance applications.

Threaded ceramic rods have unique threads that provide a safe and reliable fastening method in environments where metal components typically fail. This progress is particularly important for industries such as aerospace, automotive, and electronics, as their components are subject to high temperatures and pressures.

These rods are manufactured using proprietary processes to ensure uniformity and accuracy. In applications where corrosion resistance, wear resistance, and thermal shock resistance are crucial, they will replace traditional metal fasteners. Threads provide a sturdy connection, eliminating the need for additional sealing, thereby reducing the overall weight and complexity of the component.

Early testing has shown that the ability of threaded ceramic rods to maintain integrity at temperatures exceeding 1600 ° C far exceeds that of traditional materials. This high-temperature resistance is expected to open up new possibilities for high-temperature industrial processes and scientific research.

The introduction of threaded ceramic rods is not only an advancement in material technology; This is a leapfrog future, where the limitations of metals are no longer a constraint. As the industry continues to break through possible boundaries, the demand for materials that can work under the most demanding conditions will only grow.

Focusing on sustainability and performance, threaded ceramic rods are expected to become the cornerstone of material engineering development. As companies and researchers explore its potential, the impact of this new technology is expected to be reflected in a wide range of applications, heralding a new era of innovation and progress.