In the high-temperature industrial sector, alumina (Al₂O₃) has become one of the key materials due to its excellent high-temperature resistance, chemical stability, and mechanical strength. However, the requirements for alumina purity vary significantly across different application scenarios. How to select the appropriate alumina purity according to specific high-temperature needs? This article will analyze the scientific logic behind this technical selection by combining industry data and expert insights.

Classification of Alumina Purity and Its High-Temperature Performance

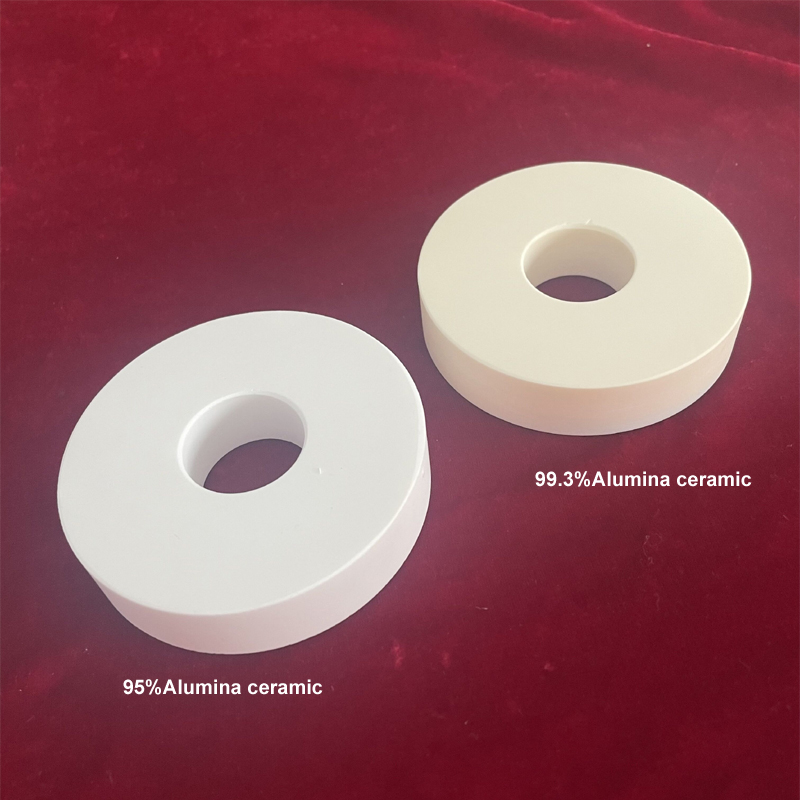

Alumina purity is usually divided into three grades:

1. Industrial grade alumina(85%-95% purity): Suitable for cost-sensitive scenarios such as refractory materials and ceramic substrates. However, due to its high impurity content, structural degradation may occur under long-term high temperatures.

2. High-purity grade alumina(99%-99.5% purity): Used in high-temperature furnace linings, catalyst supports, etc. Reduced impurities can significantly improve creep resistance and corrosion resistance.

3. Ultra-high-purity grade alumina(≥99.9% purity): Specifically designed for cutting-edge fields such as semiconductors and laser crystals, it can maintain a stable crystal structure at extreme temperatures (>1600°C).

According to research in the journal 《Advanced Ceramic Materials》for every 0.5% increase in purity, the flexural strength of alumina at 1400°C can increase by 8%-12%, but the production cost may double.

Matching Logic for High-Temperature Application Scenarios

Refractory Materials and Metallurgical Industry

Industrial furnace linings typically use alumina with 92%-95% purity, as its cost-effectiveness meets the requirements of working conditions below 1200°C. However, in strongly alkaline environments (such as glass melting furnaces), upgrading to 99% purity is necessary to resist chemical corrosion.

Case study: A steel enterprise increased the alumina purity of blast furnace spray gun materials from 90% to 99%, extending their service life by three times.

Electronics and Energy Sector

Alumina nitride ceramic substrates (used in IGBT modules) require alumina with a purity of over 99.9% as an insulating layer to ensure a dielectric loss below 0.001 under high temperatures and frequencies. Tesla's newly released silicon carbide electric drive system employs this type of material.

- Aerospace High-Temperature Coatings

In thermal barrier coatings (TBC) for aircraft engine turbine blades, 99.5% pure alumina is used as the bond coat. It can withstand the scouring of 1600°C gas while avoiding phase transformation embrittlement caused by impurities.

Core of Selection: Balancing Performance and Cost

"The selection of alumina purity must integrate three key factors: temperature, chemical environment, and mechanical load," noted an expert from the American Society for Materials. For example:

Temperature Gradient: In scenarios with drastic temperature fluctuations (such as rocket engine nozzles), the micro-crack propagation rate of ultra-high-purity alumina is 60% lower than that of ordinary grades.

Impurity Sensitivity: The sodium ion content in lithium-ion battery separator coatings must be controlled below 10ppm; otherwise, it will trigger electrolyte decomposition.

It is worth noting that some enterprises optimize costs through "gradient purity design" — using high-purity materials only in high-temperature areas, while adopting industrial-grade alumina for other parts. According to industry estimates, this strategy can reduce overall material costs by 25%-40%.

Market Trend: Surge in Demand for High-Purity Alumina

According to a report by Global Market Insights, the global high-purity alumina market size reached $4.5 billion in 2023, with a compound annual growth rate (CAGR) of 8.3%. The driving factors include:

Expansion of third-generation semiconductor (GaN, SiC) production;

Demand for corrosion-resistant ceramic components in hydrogen energy electrolyzers;

New EU regulations requiring a 30% reduction in industrial furnace emissions by 2025, forcing enterprises to upgrade high-temperature resistant materials.

As the world's largest producer of alumina, China has achieved the localization of 99.99% purity products.

Conclusion

The selection of alumina purity represents a precise techno-economic (balance). As high-temperature industries advance toward more demanding operating conditions, the adaptability between material purity and application scenarios will become a key indicator of enterprise competitiveness. In the future, leveraging AI to simulate and predict material lifespan, as well as developing customized purity solutions, may emerge as breakthrough directions for the industry.