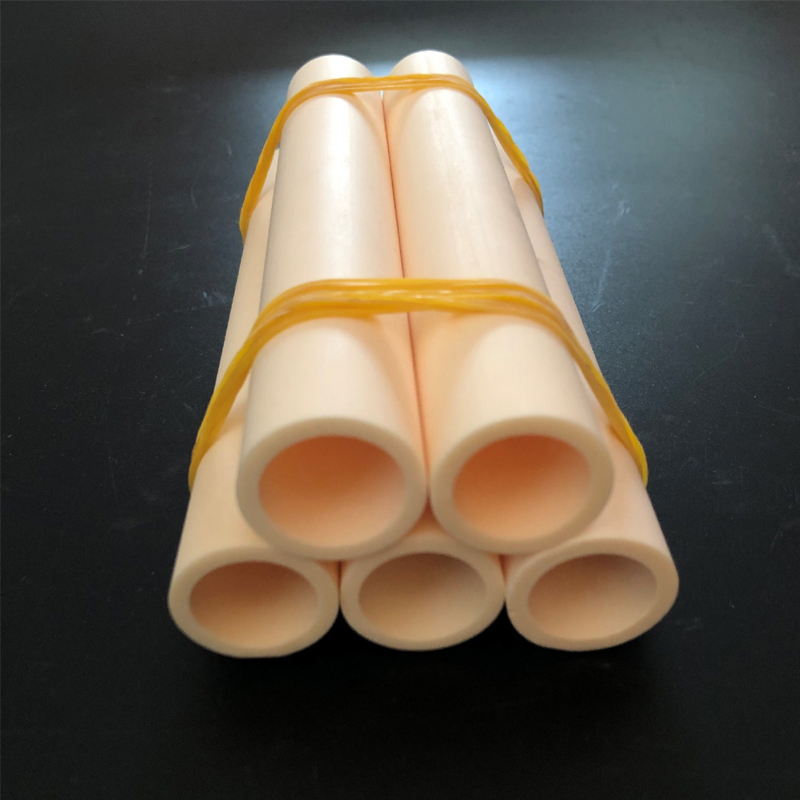

The alumina tube in the tube furnace is also called 99 ceramic corundum tube. Its characteristics are as follows:

1. High purity: Al₂O₃ content > 99% with excellent chemical corrosion resistance.

2. Good temperature resistance: long-term service temperature up to 1600℃, short-term up to 1800℃.

3. Excellent thermal shock resistance: not easy to crack.

4. High density via slip casting process.

Based on the characteristics of corundum (relatively poor thermal shock resistance), to extend the service life of corundum tubes (alumina tubes) at high temperatures and reduce operational costs, the following usage recommendations are proposed to effectively enhance their durability:

1. When using the tube furnace, the heating and cooling rates should be controlled at 5℃ per minute, and the slower the better. Thermal shock (rapid heating/cooling) is one of the main causes of alumina tube breakage.

2. Please always keep the interior of the tube clean and avoid leaving any sample residues inside to prevent chemical reactions that could cause the corundum tube (alumina tube) to crack. It is recommended that you place the test samples in a crucible before inserting them into the tube.

3. It is recommended that loading and unloading of samples be performed when the temperature is below 200℃, and the samples should be slowly moved from the edge toward the center. Excessively high temperatures during sample loading/unloading at elevated temperatures are also a major cause of corundum tube (alumina tube) breakage.

4. Please ensure that mullite furnace plugs are placed on both sides of the tube furnace's heating tube to prevent thermal radiation from damaging the silicone O-rings inside the flanges. The crucible should be placed in the middle position of the tube of the tubular electric furnace.

Alumina tubes have gained extremely widespread applications, and the market demand is also increasing day by day. Consequently, there are a growing number of alumina ceramic manufacturers. So, how should one choose a reliable alumina ceramic producer? Below is an analysis to help you make an informed decision.

1. Exquisite craftsmanship is required

Merely having ready-made equipment is not sufficient to fully guarantee the product quality of alumina ceramics; a complete set of supporting production processes is also indispensable. Therefore, the sophistication of the alumina ceramic production process is another key consideration for enterprises when selecting manufacturers. Only with advanced and refined processes can the produced products demonstrate superior performance in wear resistance, corrosion resistance, high-temperature resistance, acid-alkali resistance, and other aspects, meeting the international advanced standards.

2. The quality of raw materials should be reliable

In addition to advanced equipment and sophisticated production processes, careful selection of raw materials is also crucial to achieving superior quality in alumina ceramics. When choosing a manufacturer, enterprises should inquire about the materials used and prioritize those adopting modern engineering ceramic materials—these materials offer higher hardness and enhanced wear resistance, delivering exceptional product performance.

3. We need high-precision equipment

Due to the extremely high processing difficulty of alumina ceramics and the stringent requirements for equipment—demanding high-precision imported machinery, which involves substantial investment costs—not every manufacturer is equipped with such facilities. Therefore, when selecting an alumina ceramic manufacturer, enterprises are advised to visit the production plant in person to verify whether the manufacturer utilizes high-precision equipment.