Alumina ceramic tubes are a type of high-performance ceramic material with excellent properties such as high temperature resistance, corrosion resistance and wear resistance, thus being widely used in many fields. To meet different application requirements, various processing treatments are needed for alumina ceramic tubes applied in wear-resistant pipelines of power plants and new energy transmission pipelines.

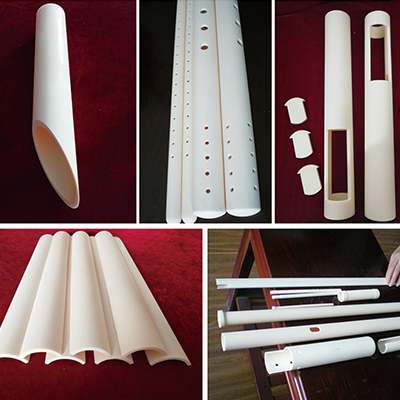

There are various methods for processing alumina ceramic tubes, among which the most common ones are machining and heat treatment. Machining mainly involves shaping ceramic tubes through grinding, cutting, drilling and other processes to achieve the required shapes and dimensions. During the processing, it is necessary to use high-precision machine tools and tools, and strictly control the processing parameters to avoid damaging the ceramic tubes.

Another processing method is heat treatment, which mainly involves subjecting ceramic tubes to processes such as sintering, melting and vitrification by controlling temperature and atmosphere, so as to improve their physical and chemical properties. During the heat treatment process, it is necessary to precisely control the temperature and time to ensure the optimal treatment effect.

In addition, there are also some special processing methods, such as electrochemical machining and laser machining. Electrochemical machining mainly etches and polishes ceramic tubes by means of electrolyte to render their surfaces smoother; laser machining, on the other hand, uses high-energy laser beams to cut and drill holes in ceramic tubes, featuring high precision and high efficiency.

In conclusion, the selection of appropriate processing methods for alumina ceramic tubes should be based on specific requirements. During the processing, it is essential to strictly control the process parameters and treatment conditions to ensure that the processing quality and performance meet the required standards. Meanwhile, it is also necessary to strengthen quality control and safety management in the production process to guarantee production efficiency and workers' safety.

Advantages of Alumina Tubes

Compared with metals and polymers, alumina ceramic tubes are the preferred choice under extreme conditions. Their general properties and durability make them an essential component in products that require long service life with low maintenance needs. This durable characteristic also makes them the top choice for manufacturing long-life products.

Other types of pipes made from various polymers or metals may require frequent cleaning or replacement. Once alumina ceramic tubes are installed, they can ensure years of service. The chemical resistance and non-conductivity of alumina tubes make them ideal protectors and insulators.