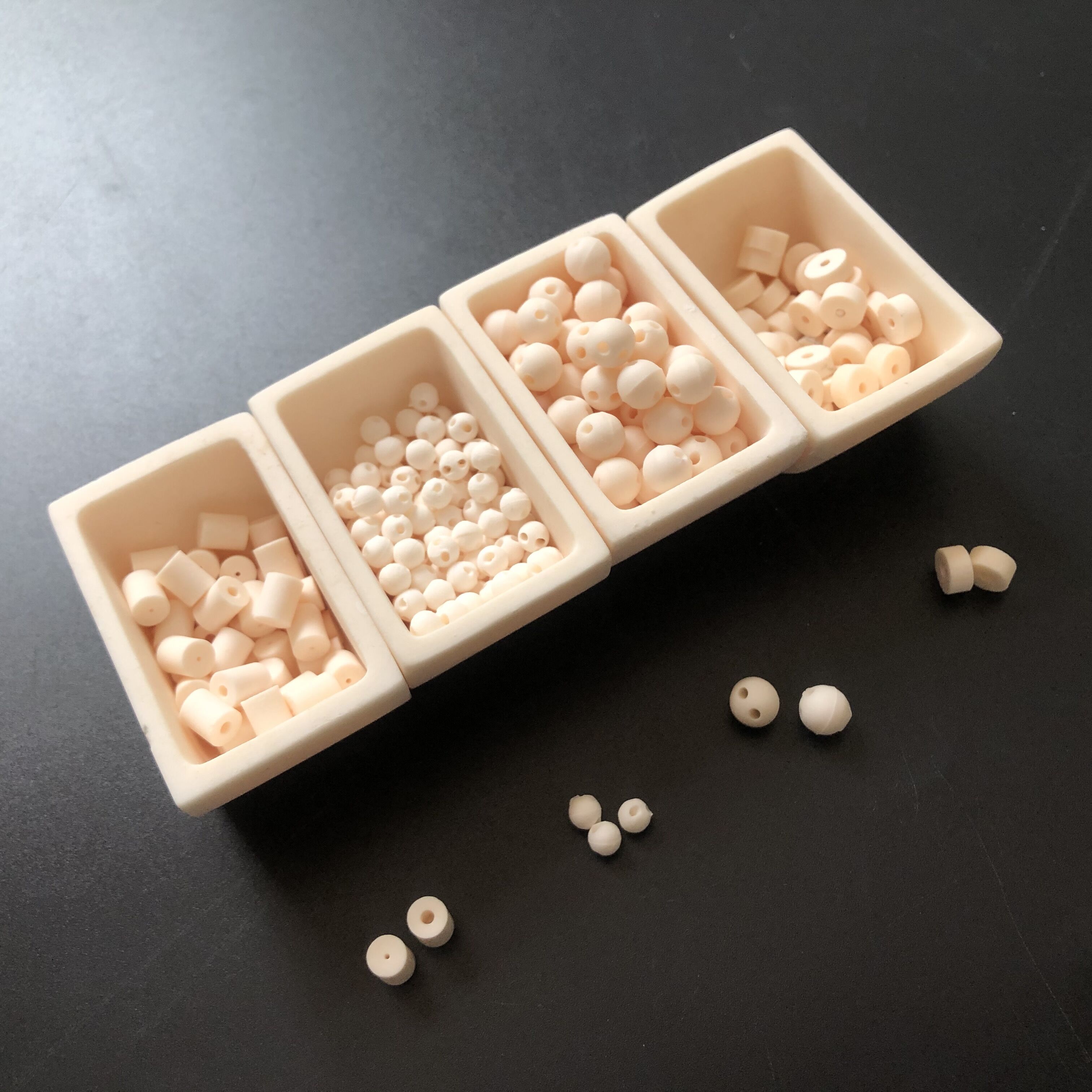

(1) Wear-resistant ceramic beads

Materials: Zirconia (ZrO₂), Aluminum Oxide (Al₂O₃), Silicon Carbide (SiC), Silicon Nitride (Si₃N₄).

Characteristics: High hardness (for instance, the hardness of zirconia beads is second only to that of diamond), strong wear resistance, and high temperature resistance (aluminum oxide beads can withstand temperatures above 1500 °C).

Applications: Ultrafine grinding and dispersion in industries such as coatings, inks, pesticides, and electronic pastes.

For example, in the roaring grinders of a coating factory, zirconia ceramic beads are colliding thousands of times per second to grind raw materials such as inks and pesticides to the nanoscale. Traditional glass beads would be shattered within a few hours in such an environment, while ceramic beads can remain as stable as Mount Tai and have a service life of several years. Data shows that the grinding efficiency can be increased by 300% when using ceramic beads, while the cost is reduced by more than half.

(2) Insulated ceramic beads

Materials: Aluminum oxide, talc, mullite, cordierite, forsterite.

Characteristics: High insulation resistance (>10¹²Ω·cm), high voltage resistance, corrosion resistance.

Applications: Encapsulation of electronic components, insulation of high-voltage equipment, interval support for wires and cables.

For example, in electronic devices such as smartphones and new energy vehicles, there are a large number of circuits and components with high voltage and high current inside. Especially in some extreme environments, such as high temperature, high humidity, strong electromagnetic interference, etc., extremely high requirements are put forward for the insulation performance of the devices. Relying on its excellent insulation performance, alumina ceramic beads can effectively prevent the occurrence of faults such as electric leakage and short circuits. Its insulation resistance is as high as 10¹²Ω·cm, which is a million times that of ordinary plastics, enabling devices such as smartphones and new energy vehicles to still operate stably in extreme environments.

(3) Porous ceramic beads

Materials: Corundum sand, silicon carbide, cordierite, aluminum oxide, diatomite.

Characteristics: High open porosity (can reach more than 50%), resistance to high temperature and high pressure, and resistance to acid and alkali corrosion.

Applications: Catalyst carriers, gas/liquid filtration, packing for bioreactors.

Example: For instance, in chemical reactions, porous silicon carbide ceramic beads can not only load the catalyst onto their pore walls, forming highly efficient silicon carbide microreactors, but also effectively transfer the reaction heat, promoting the progress of chemical reactions. Compared with metal carriers or oxide carriers, porous silicon carbide ceramic beads can better maintain the stability of the catalyst structure, extend the service life of the catalyst, improve the reaction efficiency and the purity of the products, demonstrating broad application prospects.