With the rapid development of high-temperature materials science, high-purity alumina crucibles (alumina content ≥99%) have become key tools for high-temperature experiments in laboratories and industries, thanks to their excellent high-temperature stability. They can withstand temperatures up to 1600°C, and even 1800°C in the short term. Moreover, they feature outstanding chemical stability and thermal shock resistance, being widely used in fields such as metal smelting, non-metal analysis, and thermal analysis experiments.

Ⅰ. High-temperature Performance Advantages of High-purity Alumina Crucibles

1.Ultra-high Temperature Stability

The high-purity alumina crucible operates over a wide temperature range, capable of long-term use at 1600–1750°C and short-term exposure to 1800°C—far exceeding ordinary ceramic crucibles (approximately 1000°C).

It exhibits remarkable resistance to thermal shock, showing minimal risk of cracking during heating or cooling (a recommended heating rate of 5°C/min to 10°C/min is advised). This addresses the damage issue of traditional crucibles caused by abrupt temperature changes.

2.Low Thermal Expansion Coefficient

High-purity alumina features a low thermal expansion coefficient, ensuring the crucible maintains structural stability under extreme temperatures and avoiding deformation or cracking. It is particularly suitable for experimental scenarios requiring rapid heating or cooling (such as thermal analysis tests).

3.Structural Densification

Through the slip casting process, the product has a bulk density of ≥3.88 g/cm³ and an apparent porosity of <1%, forming a dense crystalline structure that reduces the risk of material penetration or corrosion at high temperatures.

Ⅱ.Embodiment of High-temperature Stability in Practical Applications

1.Laboratory Scenarios

In metal smelting and non-metallic sample analysis, high-purity alumina crucibles can come into long-term contact with strong corrosive media such as acids and alkalis, maintaining chemical inertness and avoiding sample contamination.

Their ultra-high temperature stability makes test results more accurate, with no chemical reactions with samples, ensuring the reliability of thermal analysis data.

2.Industrial High-temperature Environments

When used in refractory furnace tubes and special wear-resistant components (such as ceramic bearings), high-purity alumina crucibles exhibit significantly better high-temperature strength and wear resistance than ordinary ceramic crucibles.

Ⅲ.How to Extend the Service Life of High-temperature Stability?

1.Standardized Operation Recommendations

Avoid sudden cooling and heating, and raise/lower temperatures slowly; regularly inspect the integrity of the crucible and replace damaged components in a timely manner.

After use, it is recommended to clean by washing with water or soaking in 10% hydrochloric acid (avoid strong acid corrosion) for repeated use.

2.Customized Selection

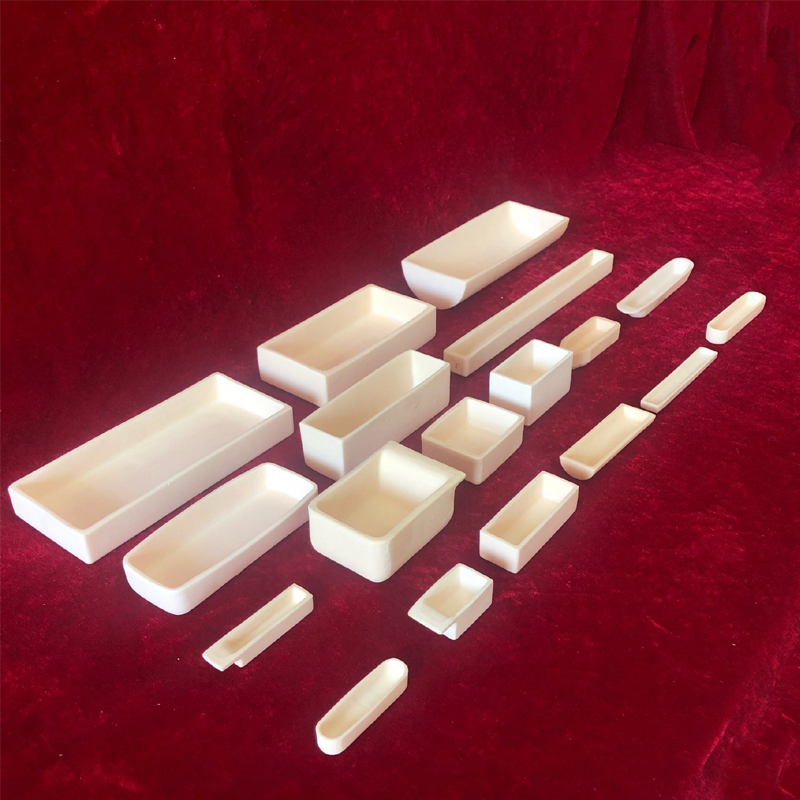

A variety of specifications (such as 5mL-5000mL) are available in the market. Users can choose arc-shaped, straight or special-shaped crucibles according to experimental needs to match specific high-temperature processes.

Conclusion

With its ultra-high temperature stability at 1600°C, excellent corrosion resistance, and structural strength, high-purity alumina crucibles have become benchmark products in the field of high-temperature experiments. Along with advancements in material technology, their application potential in high-end scenarios such as new energy material synthesis and semiconductor manufacturing will be further unleashed.