In the field of materials science, customized porous alumina ceramics are gradually becoming the focus of attention in numerous industries, relying on their unique properties. This material, with its outstanding application advantages, brings innovative solutions to multiple fields.

Unique physical and chemical properties lay the foundation for applications.

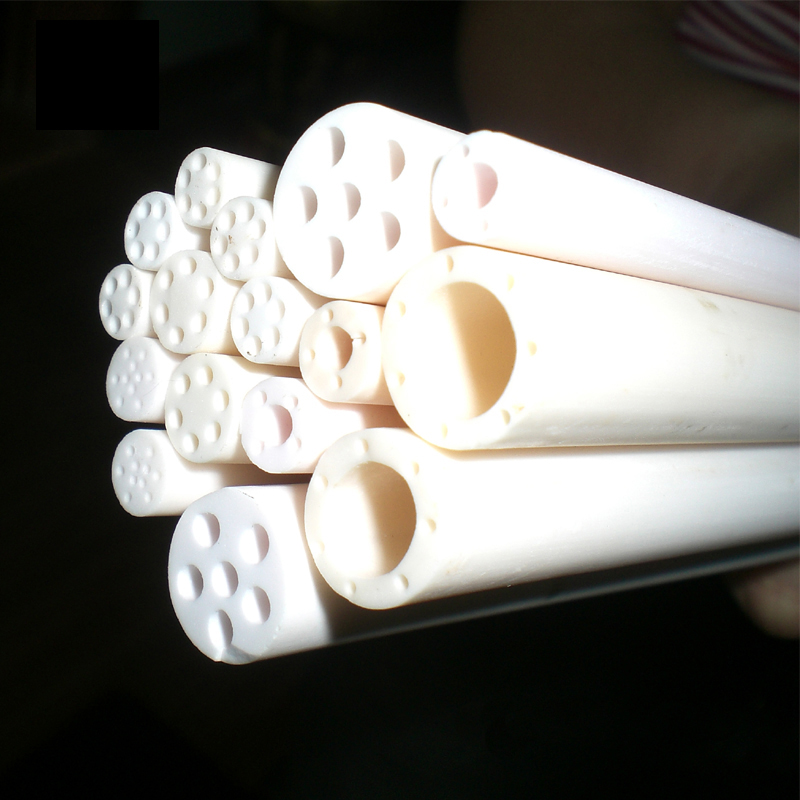

Porous alumina ceramics possess a series of remarkable characteristics. It has high mechanical strength and can maintain structural stability when subjected to external forces. This characteristic stems from its microstructure. Through special preparation processes, the particles inside the ceramics are closely bonded to form a sturdy framework. For example, during the preparation process, by adjusting parameters such as the ratio of raw materials and the sintering temperature, the microstructure of the ceramics can be optimized, thereby enhancing its mechanical strength. Compared with some traditional materials, such as ordinary ceramics or certain metal materials, porous alumina ceramics can withstand greater pressure without cracking or deforming under the same volume or weight.

At the same time, it also has good chemical stability. In different chemical environments, porous alumina ceramics can resist the erosion of most chemical substances. Whether in acidic, alkaline or some corrosive organic solvents, its chemical properties can remain relatively stable. This gives it extremely high application value in industries that are prone to contact with various chemical substances, such as the chemical industry and food processing. For example, the use of porous alumina ceramics in components such as the linings of reaction kettles and pipelines in chemical production can effectively extend the service life of the equipment and reduce the equipment damage and safety risks caused by chemical corrosion.

Outstanding Performance in the Field of Purification and Separation

In the field of purification and separation, customized porous alumina ceramics demonstrate unique advantages. By precisely controlling the pore size, efficient separation of substances with different particle sizes can be achieved. In sewage treatment, porous alumina ceramics can effectively intercept impurities such as suspended solids and colloids in sewage, while allowing water molecules to pass through, thus achieving the purpose of purifying water quality. Moreover, its characteristics of super lipophilicity and super oleophobicity make it perform excellently in oil-water separation. When in an oil-water mixed environment, it can selectively adsorb the oil phase while repelling the water phase, realizing rapid and efficient separation of oil and water. This characteristic is of great significance for treating marine oil pollution, industrial oily wastewater, etc., providing a reliable technical means for environmental protection.

Innovative Support in the Field of Mechanical Manufacturing

In the field of mechanical manufacturing, porous alumina ceramics also play an important role. Taking air bearings as an example, porous alumina ceramics, as key components, directly affect the overall performance of air bearings. Through optimized design and material modification, the performance of air bearings can be significantly improved. For instance, by adding specific pore-forming agents during the preparation process and through solid-phase sintering, ceramic materials with appropriate porosity and pore size distribution can be obtained. Air bearings made of this material can form a stable gas film during operation, effectively reducing frictional resistance and improving the rotational speed and accuracy of the bearings. Experimental data show that when the porosity is increased from 5% to 25%, under the conditions of a fixed gas supply pressure and gas film thickness, the load-bearing capacity of the air bearings can be greatly increased from 94 N to 523 N. This not only improves the operating efficiency of mechanical equipment but also extends the service life of the equipment, providing strong support for the development of the high-end equipment manufacturing industry.

Customized porous alumina ceramics, with their excellent properties in aspects such as mechanical strength and chemical stability, as well as their outstanding application advantages in multiple fields like purification and separation, mechanical manufacturing, and radar absorption, are gradually becoming an important force in promoting technological innovation and development across various industries. With the continuous in-depth research in materials science, it is believed that porous alumina ceramics will showcase their unique charm in more fields and make greater contributions to the progress of human society.