As a high-performance ceramic material primarily composed of alumina(>99.3%), corundum tubes have witnessed a surge in demand across advanced industries such as semiconductors, aerospace, and new energy, owing to their exceptional properties including high-temperature resistance, corrosion resistance, and superior hardness. Industry data indicates that China's precision corundum tube market is projected to exceed RMB 8.5 billion in 2025, with a compound annual growth rate (CAGR) of 28%. Customized products are expected to account for over 40% of the total market share.

Analysis of Characteristics of Precision Corundum Tubes

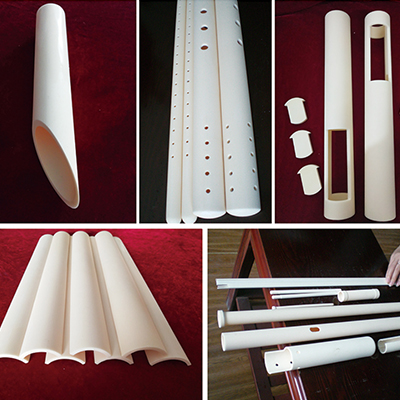

Classification System: Precision corundum tube products can be systematically categorized according to different standards.By material purity grade,they are divided into three specifications: 99.5%, 99.7%, and 99.99%. Higher purity corresponds to superior performance, but it also increases processing difficulty.By shape specification,They include straight tubes, elbow tubes, special-shaped tubes, and micro-aperture tubes. Straight tubes dominate the market, accounting for approximately 80% of the production output.

Manufacturing Process: The production of precision corundum tubes involves an extremely complex process, encompassing multiple stages such as raw material purification, forming, sintering, and finishing. The preparation of high-purity alumina powder serves as the foundation, typically achieved through the modified Bayer process or thermal decomposition of ammonium aluminum carbonate. Forming techniques include isostatic pressing, slip casting, and hot die casting, with corresponding methods selected based on the product's shape and dimensions.

Surge in Market Demand: Customization of Precision Corundum Tubes Ushers in a Golden Development Period

In recent years, the market demand for customized services of precision corundum tubes has shown an explosive growth trend. Industry statistics show that the overall market size of China's corundum tube industry reached 8.5 billion yuan in 2023, with a steady compound annual growth rate (CAGR) of about 6.5% from 2019 to 2023. In the field of precision corundum tubes, the growth curve is steeper. Especially with the rapid expansion of strategic emerging industries such as semiconductors and new energy, the demand for high-performance and customized corundum tube products is increasing at a rate of more than 25% per year. This strong market demand mainly comes from the continuous improvement of equipment performance requirements in terminal application industries and the acceleration of the domestic substitution process.

Technological Innovation Drives Leap in Customization Capabilities of Precision Corundum Tubes

In recent years, the field of precision corundum tube customization has achieved a series of technological breakthroughs, significantly improving the upper limits of product performance and the extremes of processing accuracy.

Material formulation innovation serves as the foundation. By introducing stabilizers such as zirconia and yttria, new composite materials like zirconia-toughened alumina (ZTA) have been developed, increasing the flexural strength of products from the traditional 300-350 MPa to over 450 MPa and enhancing fracture toughness by approximately 40%.

Innovation in sintering processes is crucial. The application of advanced technologies such as microwave sintering and spark plasma sintering has enabled product density to reach over 99% of the theoretical density, with grain size controlled within the range of 0.5-1 μm—far superior to the 3-5 μm level of conventional sintered products.These material-level innovations allow precision corundum tubes to meet more demanding industrial application environments.

Future Development Trends and Investment Prospects of Precision Corundum Tube Customization

The customization industry of precision corundum tubes is standing at a new development inflection point, and profound structural changes will be ushered in the next five years. In terms of market size, benefiting from the strong demand of strategic emerging industries such as semiconductors and new energy, industry analysis predicts that the market size of China's precision corundum tubes will exceed 8.5 billion yuan in 2025, with a compound annual growth rate (CAGR) as high as 28%. Among them, the demand growth rate of ultra-precision products for semiconductor equipment is expected to reach 41%.

In terms of product technology, high purity, high precision, and composite functions will become the mainstream development directions. The market share of ultra-high purity corundum tubes with a purity of over 99.99% will increase from the current 20% to more than 35%, while innovative products with composite characteristics such as thermal shock resistance and corrosion resistance will gradually replace single-function products. These trends indicate that the customization field of precision corundum tubes will enter a new development stage of simultaneous improvement in quantity and quality.