▶▶▶▶What is a ceramic crucible

Modern ceramic crucibles are high-temperature-resistant containers made from high-purity ceramic materials (such as quartz, aluminum oxide, boron nitride, zirconium oxide, etc.) as the base material through a precise high-temperature sintering process. They are mainly used for holding, smelting, and enabling reactions of various solid or liquid substances.

In essence, ceramic crucibles acquire their robust property of withstanding extreme temperatures ranging from 1600°C to 2700°C through the optimization of the lattice structure of inorganic non-metallic materials. Meanwhile, relying on their excellent chemical inertness and thermal shock stability, they have become indispensable components in scenarios such as laboratory material analysis, precious metal purification in the metallurgical industry, semiconductor monocrystalline silicon growth, and new energy polysilicon ingot casting.

Overall, its biggest feature is its ability to maintain stable morphology and performance in extreme high temperature environments, and it is not easily deformed or corroded.

▶▶▶▶Common materials of ceramic crucibles

The material is the primary factor in choosing a crucible, as it directly determines how high the crucible can withstand temperatures and what chemical substances it can resist corrosion.

1. Traditional Refractory Clay: It is made by firing raw materials such as clay and quartz. It has low cost and contains a relatively high amount of SiO₂ (silicon dioxide), belonging to acidic materials. It is mainly used for smelting acidic metals or materials, such as copper alloys. It must never be used for smelting active metals like aluminum, magnesium, and titanium—because these metals will reduce silicon from SiO₂, which severely corrodes the crucible and may even cause it to leak or perforate. It is also commonly used in small-scale casting and chemical experiments.

2. Aluminum Oxide (Al₂O₃): It is the most common type [of ceramic crucible material], with a temperature resistance range usually above 1600℃, and it possesses both high strength and excellent chemical stability. It is commonly used in metal smelting, powder sintering, laboratory analysis, high-temperature reaction vessels, and other applications. Its maximum service temperature and performance vary depending on its purity (such as 99% alumina ceramic, 95% alumina ceramic, and 85% alumina ceramic).

3. Zirconium Oxide (ZrO₂): Among all oxide ceramics, it has the highest temperature resistance (with a melting point of approximately 2700℃), but its thermal shock resistance is relatively poor. It is extremely corrosion-resistant, and exhibits excellent stability especially against molten metals (such as precious metals like platinum and palladium). It is mainly used for high-temperature smelting of precious metals and active metals (e.g., platinum, rhodium, palladium, titanium) and also applied in the sintering of special ceramics and high-temperature furnace linings.

4. Quartz (SiO₂): It is a high-temperature-resistant container made from high-purity quartz sand as the main raw material, through high-temperature melting, drawing, or rotational molding processes. Mostly translucent, it can withstand high temperatures ranging from 1200℃ to 1400℃, and is commonly used in the preparation of semiconductor materials and optical glass. Its greatest advantage lies in high purity and low impurity content, which ensures that materials are not contaminated during high-temperature processing. However, it should be noted that quartz crucibles are not resistant to alkaline substances and are prone to corrosion when in contact with strong alkalis.

5. Boron Nitride (BN): It has good thermal conductivity, self-lubricating properties, low adhesion to molten metals, and ease of processing, hence the name "white graphite". It can withstand high temperatures (approximately 3000℃) in an inert atmosphere, but oxidizes at high temperatures in air. It is an ideal material for metal forming molds, crucibles used for smelting metals (especially aluminum, copper, and semiconductor materials), and evaporation boats for vacuum aluminum plating.

6. Silicon Carbide (SiC): It possesses extremely high hardness, thermal conductivity, and thermal shock resistance. It maintains high strength at high temperatures but is not resistant to strong oxidizing acids and strong alkalis; it oxidizes slowly at high temperatures (>1000℃) in air. It is commonly used in kiln furniture (such as shelves and saggers), high-temperature heat exchangers, and aluminum liquid transport pipes. It can also be used as a high-performance crucible for smelting non-ferrous metals.

7. Magnesium Oxide (MgO): It has a high melting point (approximately 2850℃) and is an alkaline material, so it is particularly resistant to corrosion by alkaline molten slags. However, it easily reacts with water vapor to form magnesium hydroxide and pulverizes, making it difficult to store. It is mainly used for smelting alkaline materials or metals, such as nickel, uranium, thorium, etc.

``````

▶▶▶▶Common shapes and sizes of ceramic crucibles

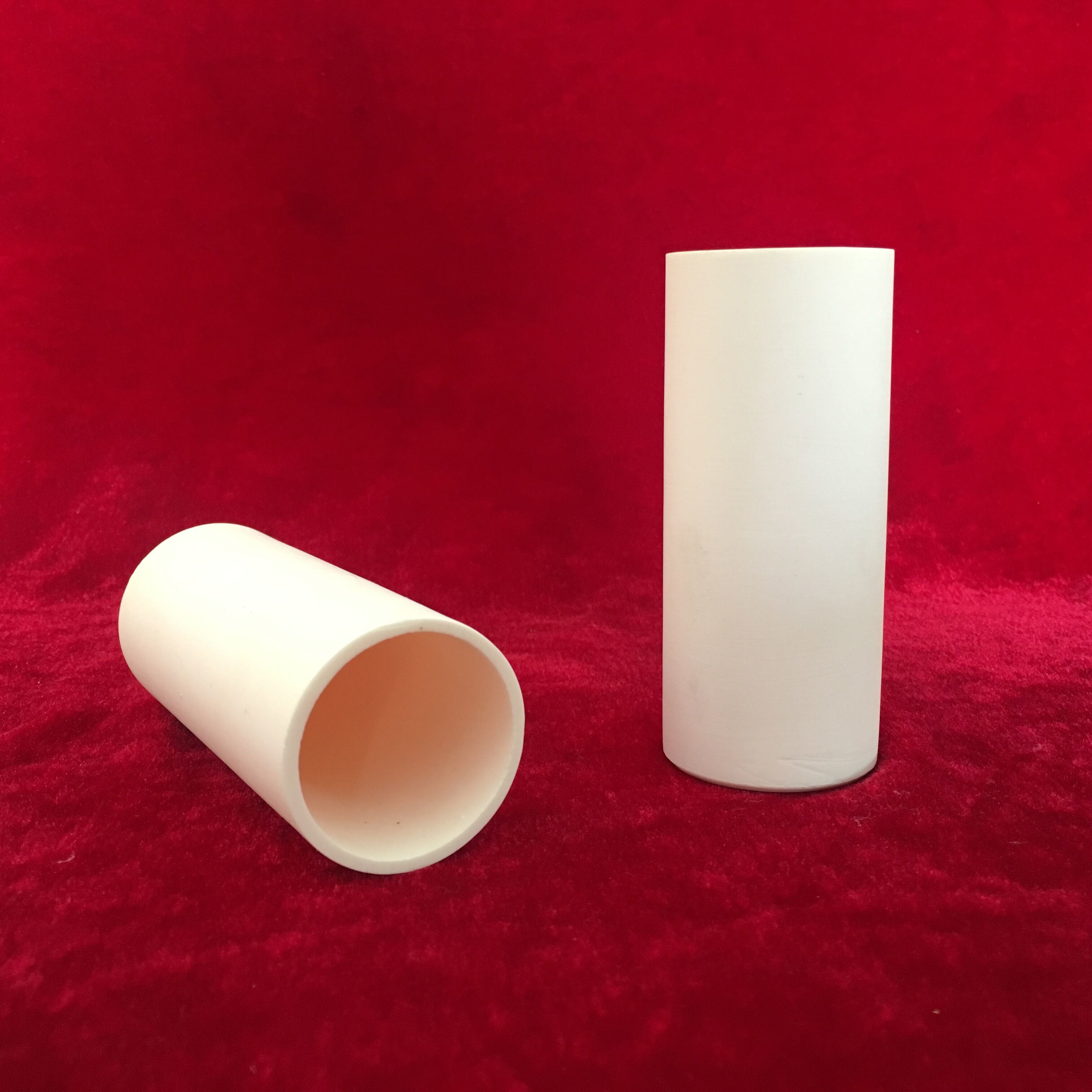

Cylindrical: Suitable for uniform heating:

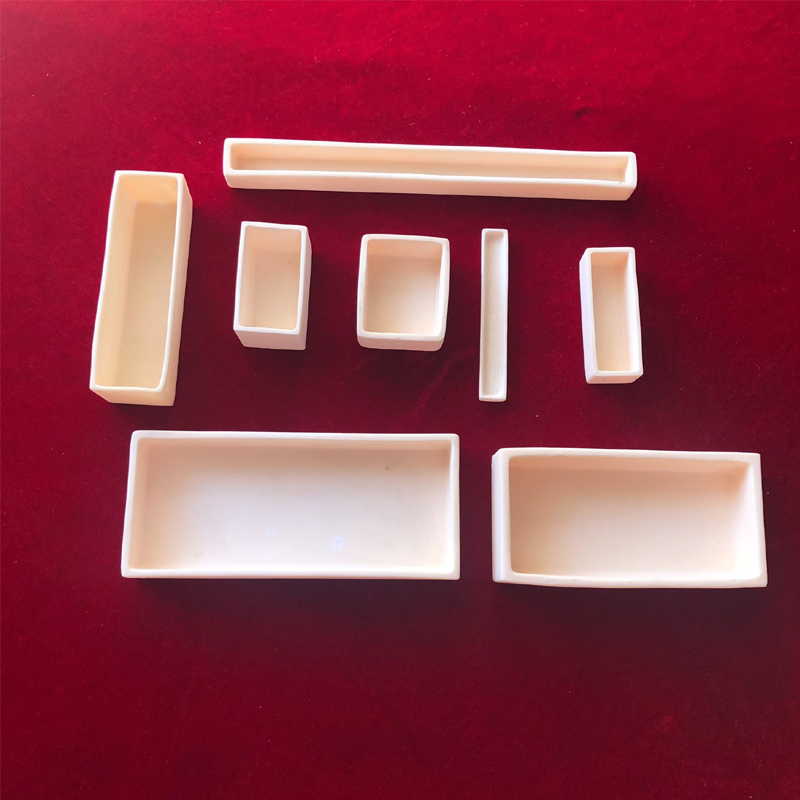

Square or rectangular: commonly used for sintering powder materials:

Deep tube type: suitable for melting metals to prevent liquid splashing out:

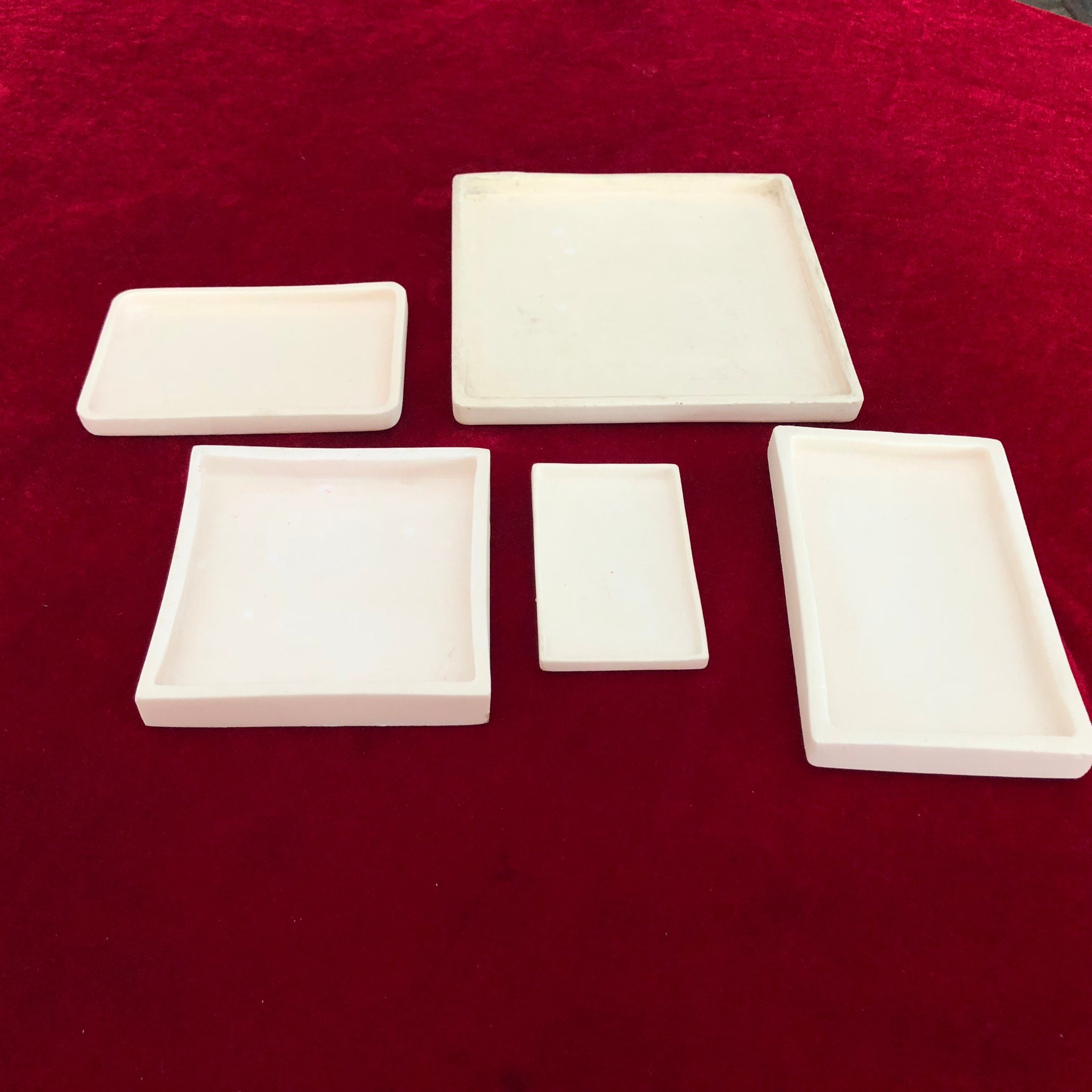

Flat type: used for ashing or evaporation:

Lided crucible: prevents material splashing, reduces heat loss, and isolates air:

Special shaped (irregular, etc.) crucible: serving specific processes, such as casting ladles, special devices for distillation and purification, etc:

Common sizes:

(1) Small size: Several tens of milliliters (such as diameter 20-50mm), used for laboratory sample analysis.

(2) Medium size: several hundred milliliters (diameter 100-150mm), used for small batch material processing.

(3) Large size: several liters or even tens of liters (diameter over 200mm), commonly seen in industrial smelting and large-scale experiments.