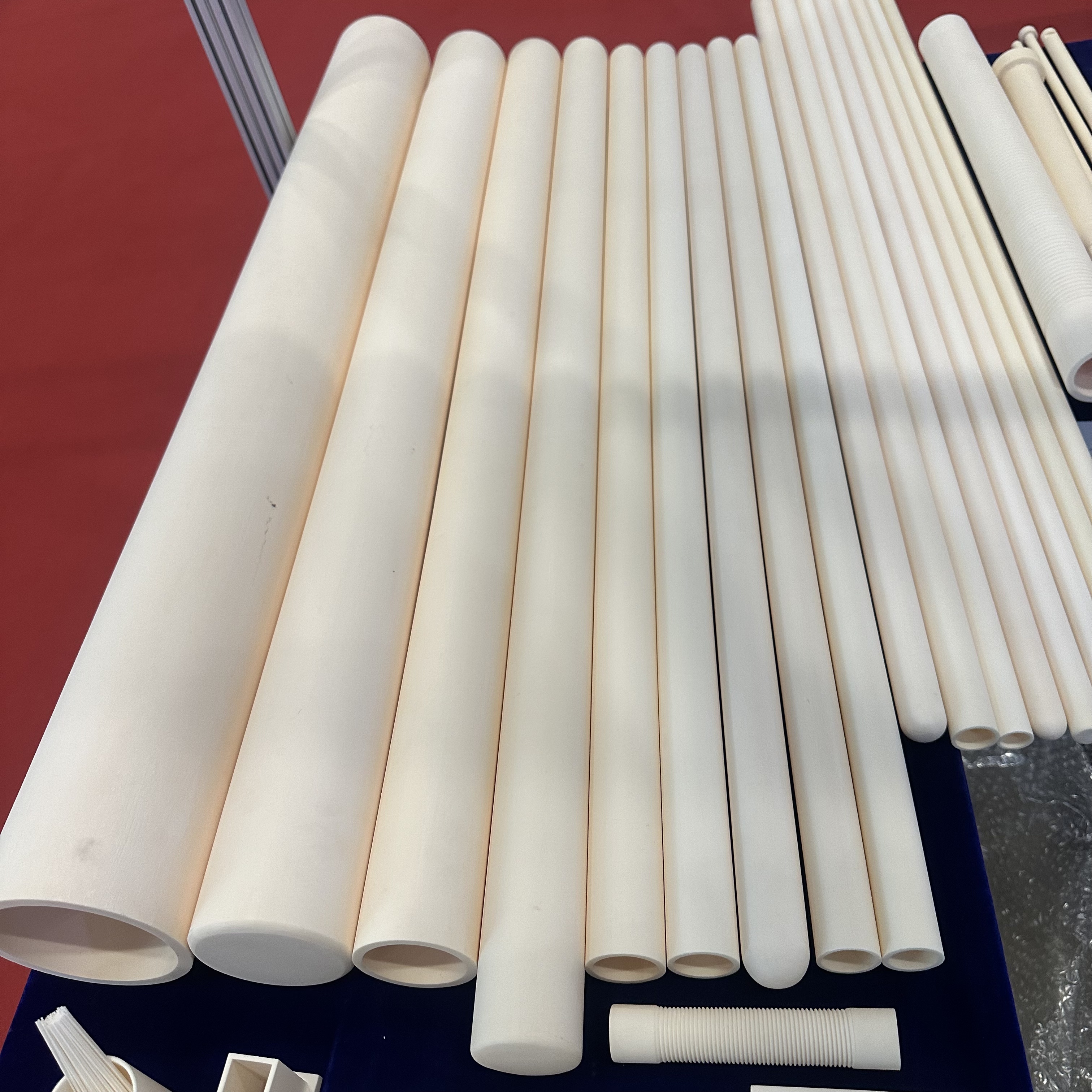

Industrial ceramics, especially alumina ceramics, have become the "hidden champions" in the field of high-end manufacturing due to their excellent hardness, wear resistance, and high-temperature resistance. In recent years, with the innovation of materials science and processing technology, the applications of alumina industrial ceramics in mines, semiconductors, new energy, and other fields have been continuously expanded, promoting the industry to move towards intelligence and greenization.

Ⅰ.Material Innovation: From Single to Composite, Comprehensively Improving Performance

1.Nanocrystalline and Composite Technology

Through nanocrystalline sintering processes, a dense microcrystalline structure is formed on the surface of alumina ceramics, achieving wear resistance 266 times that of ordinary steel linings. This extends the service life by over 10 times in mining conveying systems. Additionally, the development of composite materials has become a trend. For example:

Carbon fiber/zirconia-reinforced alumina exhibits a flexural strength of 800 MPa, suitable for aero-engine components.

Graphene-composite alumina ceramics have a thermal conductivity increased to 200 W/m·K, applied in heat dissipation modules for 5G base stations.

2.High Purity and Transparency

High-purity alumina (purity ≥ 99.99%) avoids metal ion contamination in semiconductor etching equipment, with the iron content in wafers controlled below 5 ppm. Transparent alumina ceramics have a light transmittance exceeding 80%, used in high-pressure sodium lamps and satellite optical windows, with an infrared band transmittance of 85%.

II. Process Innovation: Low-Temperature Sintering and 3D Printing Lead the Efficiency Revolution

1.Low-Temperature Sintering Technology

Traditional sintering requires high temperatures above 1,800°C, while new processes such as foaming-dry pressing reduce the temperature to 1,400–1,600°C, cutting energy consumption by 40%. Meanwhile, the density reaches over 99%, and dielectric properties are significantly improved. Microwave sintering technology further reduces carbon emissions by 30%, complying with green manufacturing standards.

2.3D Printing and Intelligent Processing

3D printing technology enables precision manufacturing of complex-structured ceramic components (such as aerospace turbine blades) with an accuracy of ±0.1 mm, shortening the delivery cycle by 40%. AI algorithms combined with five-axis (five-axis ) precision engraving machines optimize processing paths, improving efficiency by 40%. Defect detection achieves micron-level identification through X-ray CT and AI, boosting the yield rate from 70% to 95%.

III. Application Expansion: From Industrial "Teeth" to High-End Equipment

1.Reliability in Extreme Environments

Alumina ceramics reduce particle impact through large-curvature design in mining conveying systems, extending the service life of elbows from 3 months to 3 years. In rocket engines, its thermal insulation tiles can withstand 1,600°C high temperatures, with a weight only 1/3 of that of metals.

2.Medical and New Energy Fields

Third-generation alumina ceramic artificial joints with grain refinement to 2–3 μm have a fragmentation rate reduced to 0.1% and a service life exceeding 20 years. In hydrogen fuel cells, the hydrogen embrittlement resistance of ceramic linings reduces pipeline leakage rate by 99%.

IV. Green Manufacturing and Industry Future

1.Sustainable Development Pathways

Enterprises achieve separation of ceramics and metal substrates through recycling design, with a metal recovery rate of 95%. Air-drying processes and waste reuse technologies reduce energy consumption by 10%, and solid waste utilization exceeds 70%.

2.Market Prospects

The market size of alumina ceramics in China reached 18.5 billion yuan in 2024, and is expected to exceed 30 billion yuan by 2030. Demand growth in semiconductor packaging and biomedical fields will reach 12% and 9.3% respectively.

Conclusion

The innovation of alumina industrial ceramics represents not only a victory in materials science but also the deep integration of manufacturing processes and intelligent technologies. With the cost of domestic equipment (such as diamond tools) decreasing by 60% and collaborative breakthroughs in the global industrial chain, China's ceramic industry is shifting from "following" to "leading," providing "hardcore" support for high-end manufacturing.