High-purity alumina ceramic sheets with 99.3% alumina content are playing an increasingly important role in modern automobile manufacturing by virtue of their excellent performance characteristics, and are mainly applied to the key components that improve vehicle performance, reliability and intelligence.

In the field of automotive engines, the excellent high-temperature resistance and thermal insulation properties of 99.3% alumina ceramic sheets are fully utilized. For instance, wrapping the engine combustion chamber with these plates for thermal insulation can effectively reduce heat loss, which can be combined with exhaust gas turbochargers to recover exhaust energy. Tests have shown that this technology can significantly increase the thermal efficiency of diesel engines to 48%, while also helping to reduce fuel consumption and enable rapid start-up of diesel engines. Its high purity also ensures that the material maintains excellent chemical stability and structural strength even in harsh environments exceeding 1000 degrees Celsius.

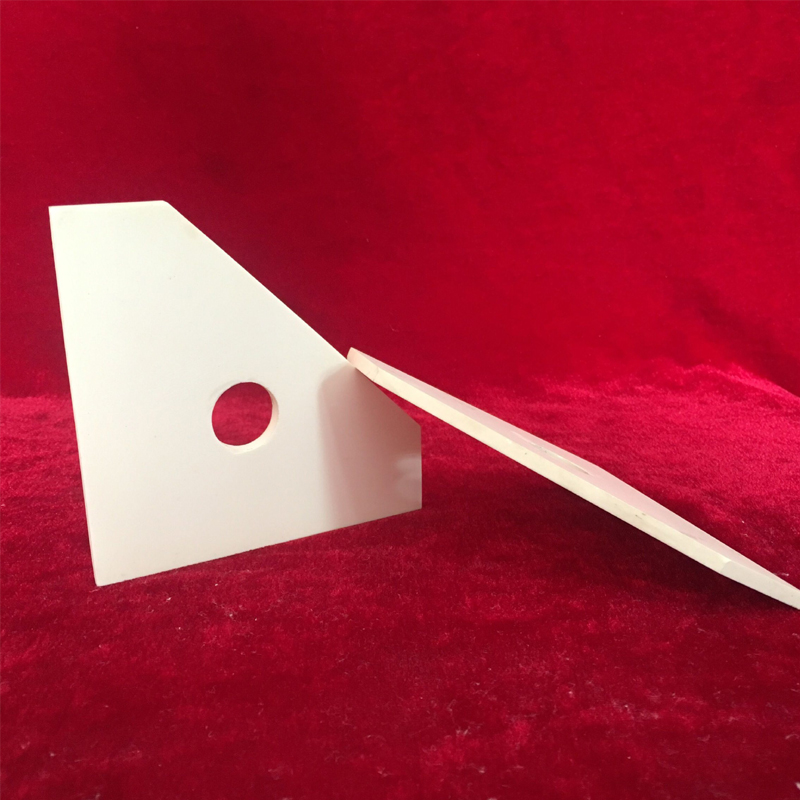

Automotive sensors need to withstand harsh environments such as high temperature, low temperature, vibration and humidity for a long time. With its excellent heat resistance, corrosion resistance, wear resistance and good electrical insulation properties, 99.3% alumina ceramic sheet has become an ideal material for manufacturing substrates and housings of various automotive sensors (e.g., temperature and pressure sensors). High purity ensures better material uniformity and reliability, which guarantees the stability of sensor signal transmission, thus meeting the requirements of automotive sensors for miniaturization, long service life and high precision.