High Purity Alumina Tube

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000 -10,000 / month(Looking for distributors)

A. The surface of the alumina ceramic tube is flame retardant and has good fire resistance. Does not affect the performance of the alumina ceramic tube at a high temperature of 1700 degrees.

B. Alumina ceramic tube is the nemesis of all acid and alkali items and other chemicals. Whether it is chemical solvents, corrosive agents or other chemical dyes, they will not affect the surface of the alumina ceramic tube.

HIGH PURITY ALUMINA TUBE

One of the standout features of the Alumina Ceramic Tube is its exceptional compressive strength. This tube can withstand immense pressure and maintains its structural integrity, even under the harshest conditions. Whether your application involves heavy machinery or high-pressure systems, this ceramic tube will not disappoint.

We only make high purity alumina ceramics

1. High-purity alumina content 99.3% -99.5%, other alumina ceramics 92% -99%.

2. The color of high purity alumina product is milky white, and other products are pink or white. The higher the purity, the more transparent the color.

3. Alumina is a refractory material, the higher the purity, the better the refractory effect

4. After high-purity alumina ceramics are fired and cooled in a 1800-degree high-temperature kiln, the products are not easy to break when they encounter high temperatures. Other ceramics are fired at 1500 ℃ ~ 1800 ℃.

5. The volume density of high-purity alumina> 3.92 g / cm3 has a smooth surface and is not easily corroded by chemicals. The bulk density of other ceramics is> 3.70 g / cm3 ~> 3.85 g / cm3.

6. High purity alumina has good hardness and good wear resistance.

7. High purity alumina products have a longer service life.

Instructions for use

When using alumina furnace tubes, it is best to control the heating and cooling rate to 5 degrees / minute, the slower the better.

Rapid cooling and rapid heating are one of the main reasons for the rupture of the alumina furnace tube. Our products have good resistance to quenching and heating.

Please keep the alumina furnace tube clean at all times, do not leave some samples in the alumina furnace tube, one side chemical reaction and cracking of the alumina furnace tube. It is recommended to put the test sample into the crucible and alumina furnace tube.

During lofting and sampling, it is best to be within 200 degrees and slowly push from the edge to the middle. High temperature sample delivery and sampling is also the main reason for corundum tube rupture.

Make sure to place mullite plugs on both sides of the alumina furnace tube to prevent heat radiation from damaging the silicone ring in the flange. The crucible should be placed in the middle of the alumina furnace tube.

Recommended products

Ceramic tray:

Corrosion resistance, high fire resistance and good chemical stability.

Used in laboratory extraction, burning, mineral, chemical and other industries.

Ceramic cone crucible:

Fire resistance, corrosion resistance and wear resistance.

Used in metallurgy, chemical industry, papermaking and other industries.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | - |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Cold compressive strength | MPa | 350 |

6 | 20ºC leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600ºC |

8 | Bonding in high temperature | not bonded in 1600ºC | |

9 | 20-1000ºC coefficient ofthermalexpansion | mm.10-6/ºC.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20ºCdirect current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000ºC MΩ | ≥0.08 |

1300ºC MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550ºC | |

15 | Maximum working temperature | ºC | 1800 |

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

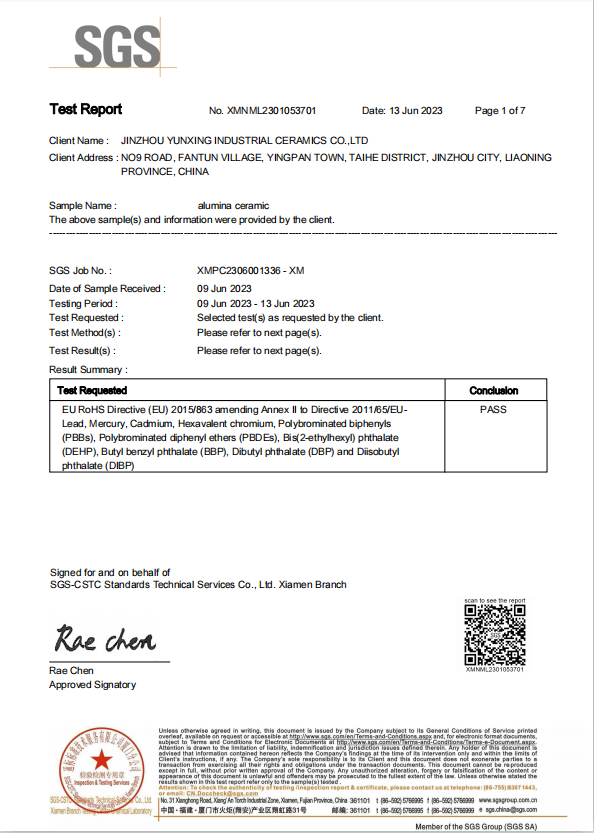

Our certificate

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.