Manufacturing Technology of Alumina Ceramics

Manufacturing Technology of Alumina Ceramics

The production of alumina ceramics has something in common with the production of traditional ceramics.

A good alumina ceramic product requires good raw materials+good molding process+good sintering system+good grinding process+other excellent production links.

Alumina ceramic materials generally refer to α alumina. According to the type of ceramic you want to make, choose the corresponding materials, such as dielectric ceramic. We mainly look at whether its sodium oxide content is low sodium alumina powder.

Wear-resistant ceramics we have to look at the D50 of his powder and the overall particle size distribution of its powder. Some of the main indicators we look at for alumina materials are as follows: alumina purity, content of various impurities, alpha conversion rate, average particle size of powder, i.e. D50, overall particle size distribution of powder, primary crystal size of powder, specific surface area, green embryo density, sintering density, shrinkage rate, etc.

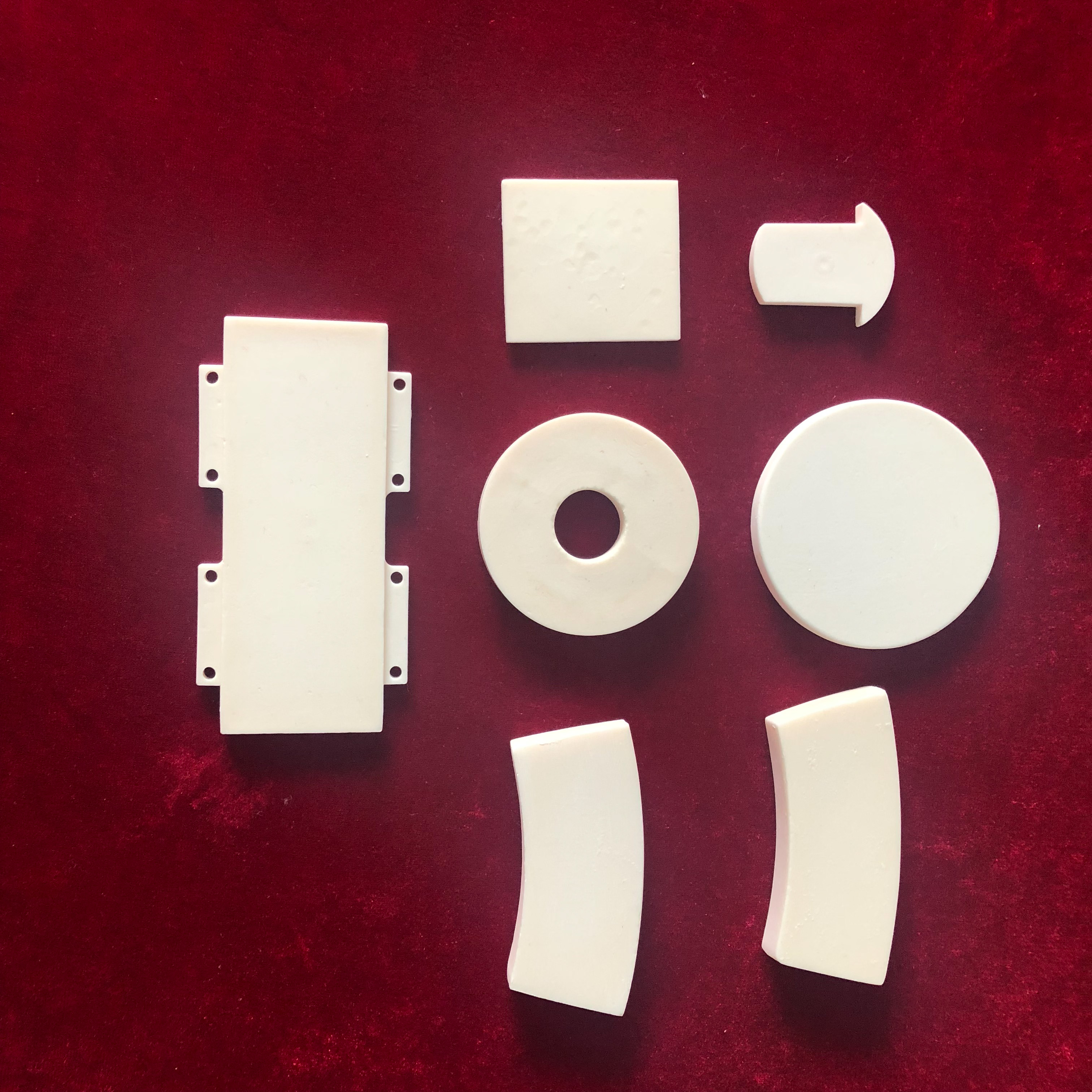

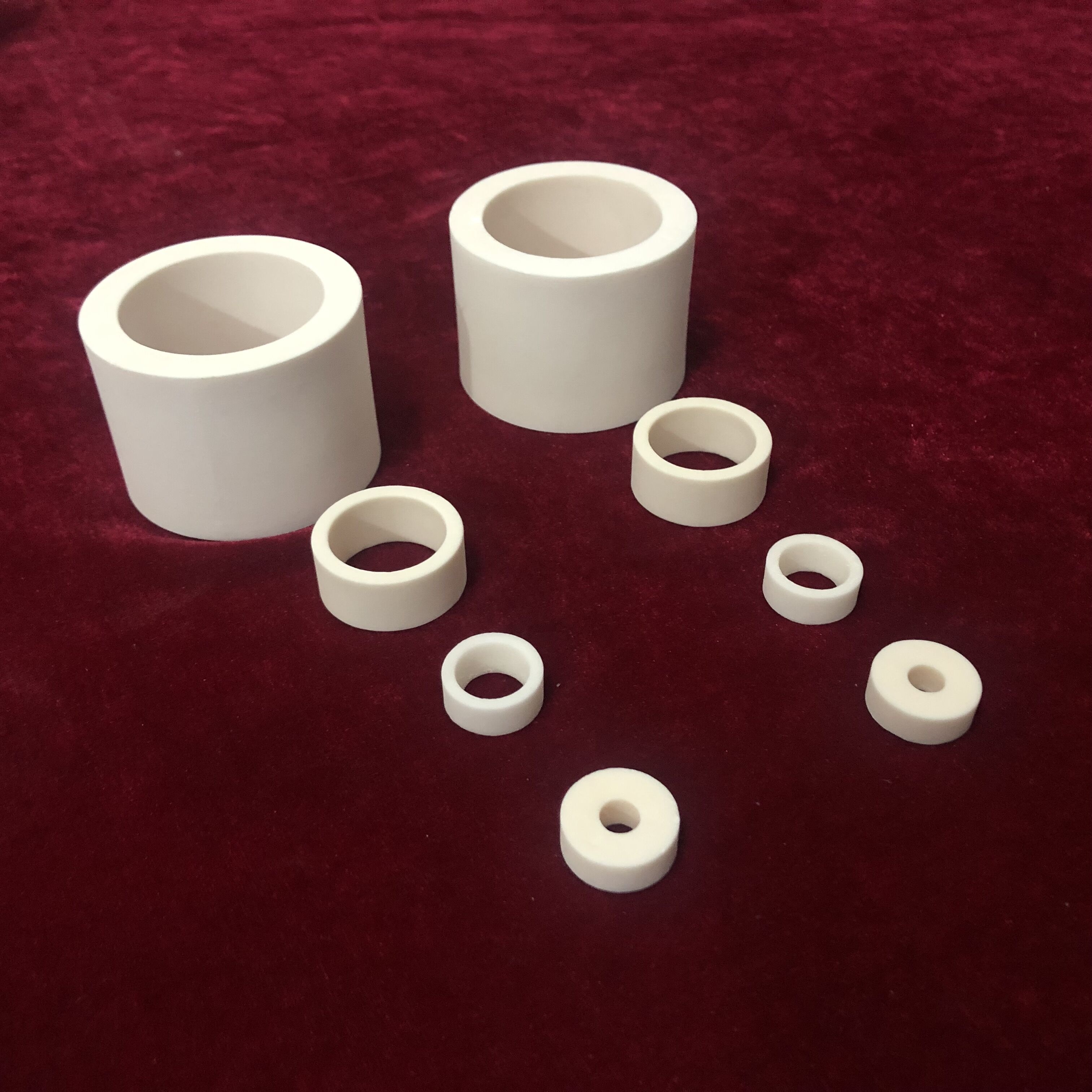

Our Company producing the 99.3%-99.7% high purity alumina ceramic products.