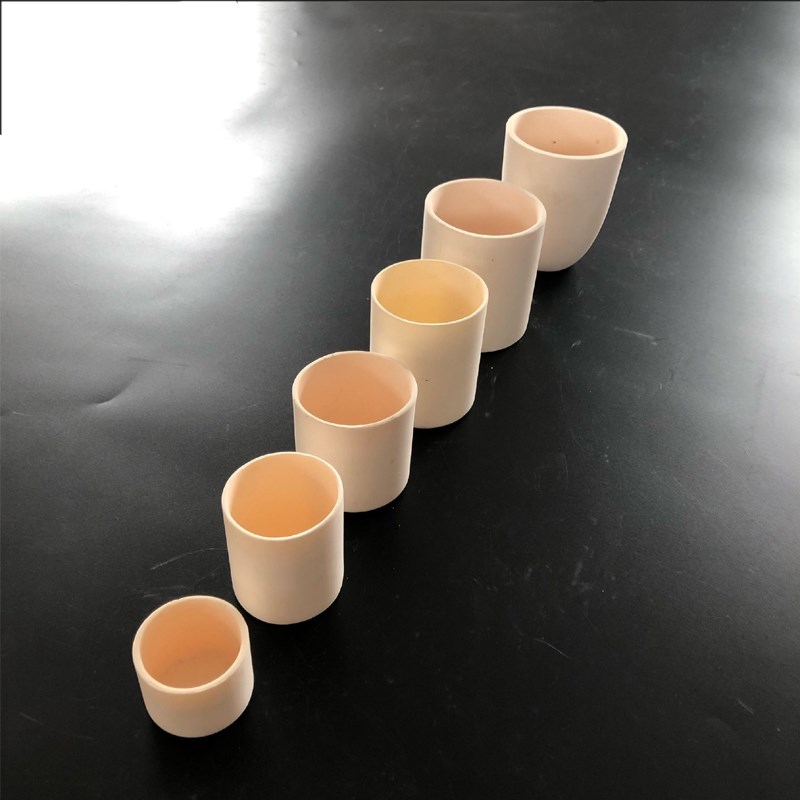

Alumina Refractory Ceramic Crucible

- YUNXING

- China Jinzhou

- 5-30 Days

- 3,000-5,000/month(Looking for distributors)

A. Has high thermal conductivity. The rapid heat transfer between the sample and the crucible ensures that there is a very small temperature difference between the two and the temperature distribution is uniform.

B. Ultra-high temperature stability, wide operating temperature range, higher operating temperature up to 1750 ℃, high repeatability, washing with water or 10% hydrochloric acid, drying, can be used repeatedly, without affecting the experimental results.

Alumina Refractory Ceramic Crucible

My factory looking for distributors.

Alumina crucibles also contain thermal analysis crucibles. Thermal analysis crucibles are mainly used for laboratory analysis. TGA instruments are used. Thermal analysis crucibles have high thermal conductivity and fast heat transfer between the sample and the crucible to ensure that there is a very small amount between the two Temperature difference, uniform temperature distribution. The structure and performance are stable. The high-purity powder cooperates with the precisely controlled high-temperature sintering process to form a dense and uniform micro-crystalline phase structure to ensure that there is no peak during use, and it is difficult to physically or chemically react with the analysis sample. Ultra-high temperature stability, wide operating temperature range, higher operating temperature up to 1750 ℃, high repeatability, washing with water or 10% hydrochloric acid, drying, can be used repeatedly, without affecting the experimental results.

Alumina crucible has a wide range of uses. It can be used in various laboratory metal and non-metal sample analysis and melting materials. It can also be used in shuttle kilns and push plate kilns to burn color materials, colorants, frit, pigments, luminescent materials, etc. . Small experimental kiln, experimental electric furnace adjustment formula and other purposes. Melting metals, precious metals, optical glass, analysis and firing of mineral raw materials such as rare earths, and firing of high-temperature products such as ceramic powder.

Recommended products:

Ceramic tray

Corrosion resistance, high fire resistance and good chemical stability.

Used in laboratory extraction, burning, mineral, chemical and other industries.

Ceramic parts

It has the characteristics of high temperature resistance, corrosion resistance, thermal shock resistance,

high mechanical strength, excellent electrical performance, etc. It is widely used in industrial equipment manufacturing and other fields.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: Alumina ceramic

3. Lead time: pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T;

7. Shipment: by sea, by air, by courier, by post, etc.

8. We accept customization.

9.We have professional designers.

10.Why alumina crucible is used?

Alumina Crucible Applications

Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures. Used as a protector for high- temperature thermal couples. Used as a material for the chemical industry due to its high corrosion resistance.

11.What are the materials in alumina crucible?

Al2O3 Alumina 99.3% with traces of MgO Magnesia and SiO2 Silica.

Maximum usage temperature: 1700°C.

Good resistance to thermal shock.

High electrical resistivity.

Good mechanical resistance.

Feedback