Alumina Industrial Ceramic Crucible Boat

- YUNXING

- China Jinzhou

- 5-30 Days

- 3,000-5,000/month(Looking for distributors)

The alumina industrial ceramic boat has:

1. High purity alumina, alumina content is greater than 99%

2. Chemical resistance

3. High temperature resistance, can be used normally at 1800℃

4. It is resistant to rapid cold and heat, and is not easy to crack.

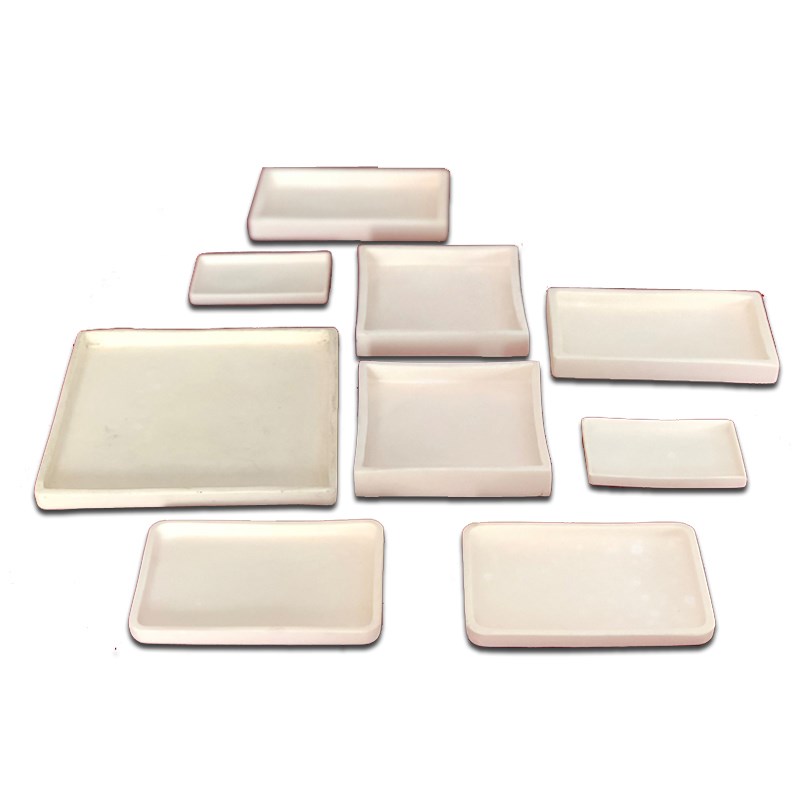

Alumina Industrial Ceramic Crucible Boat

My factory looking for distributors.

No: 114#

Shape: Rectangle

Capacity: 55 ml

Size: 100*40*18*δ2 mm

Advantages of alumina ceramic crucible:

(1) Easy to wash and keep clean.The glaze of ceramic crucible is bright and delicate, and it is easy to wash after being stained.

(2) Porcelain pores are very few, water absorption is very low.The solution stored in ceramic crucible and sealed tightly can prevent the solution from volatilization, penetration and the invasion of external bacteria.

(3) stable chemical properties, durable.This point is better than metal products such as copper, iron, aluminum, etc., ceramic crucible has a certain acid, alkali, salt and the ability of atmospheric carbonate gas erosion, not easy to react with these substances, not rust aging.

(4) good thermal stability, slow heat transfer.Ceramic crucible has the performance of not easy to burst when undergoing the change of sudden heat and sudden cooling of certain temperature difference, this point it is superior to glassware, it is a bad conductor of heat, heat transfer is slow, used to hold boiling water or boiling hot solution, when the end is not too hot.

Recommended products

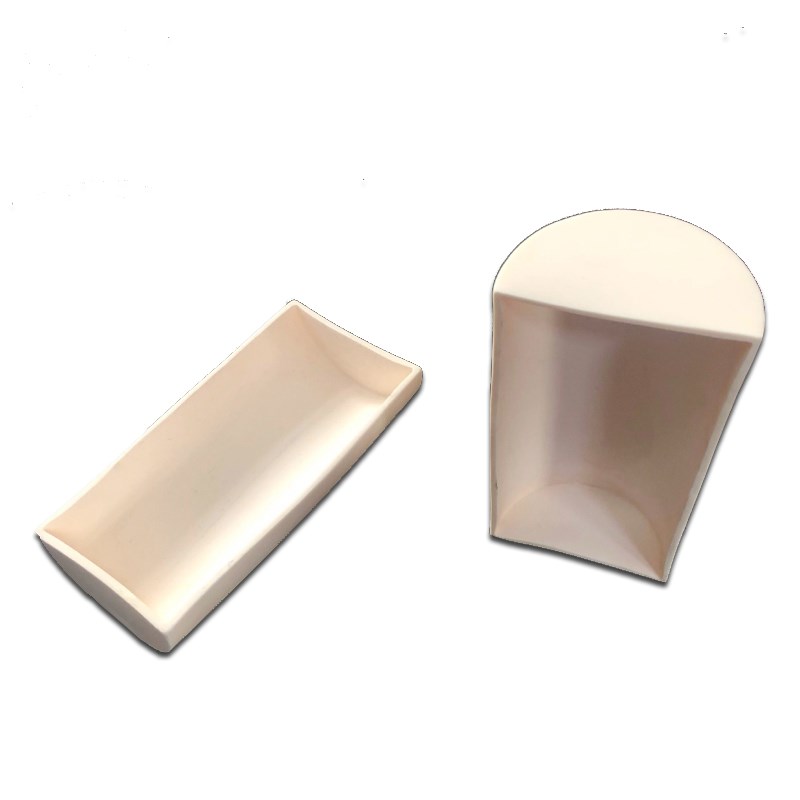

Conical crucible:

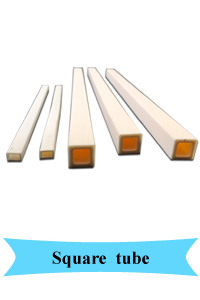

Small diameter tube:

Used in various industrial furnaces Field, do furnace tube,

Support Insulation, threading And other uses.

corrosion resistence, High temperature resistance,

insulation.

Perforated pipe:

A wire sleeve used for thermocouples.

High temperature resistance, insulation, high temperature

stability Qualitative good,

one-point numerous-temperature is aiso realizable in porous ceramic insulators.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Other dimensions, price reference table

| NUMBER | OD*ID*H | ML(CC) | SHAPE | PRICE($) |

| 1 | 36*25*59 | 26 | STRAIGHT | 1.45 |

| 2 | 41*35*41 | 40 | STRAIGHT | 1.45 |

| 3 | 24*20.8*50.8 | 20 | STRAIGHT | 1.16 |

| 4 | 45*41*62 | 75 | STRAIGHT | 2.17 |

| 5 | 50*46*60 | 90 | STRAIGHT | 2.17 |

| 6 | 60*55*60 | 130 | STRAIGHT | 2.75 |

| 7 | 50*45*140 | 215 | STRAIGHT | 8.12 |

| 8 | 72*55*200 | 450 | STRAIGHT | 20.29 |

| 9 | 190*180*124 | 2870 | STRAIGHT | 65.22 |

Alumina purity test report

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Alumina purity test report

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: Alumina ceramic

3. Lead time: pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T;

7.Why alumina crucible is used?

Alumina Crucible Applications

Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures. Used as a protector for high-temperature thermal couples. Used as a material for the chemical industry due to its high corrosion resistance.

8.What is the maximum temperature for alumina crucible?

The temperature range of alumina crucibles is typically between 1600°C to 1800°C.

9.Is alumina harder than zirconia?

Alumina is Harder than Zirconia, So It Must be More Wear ...