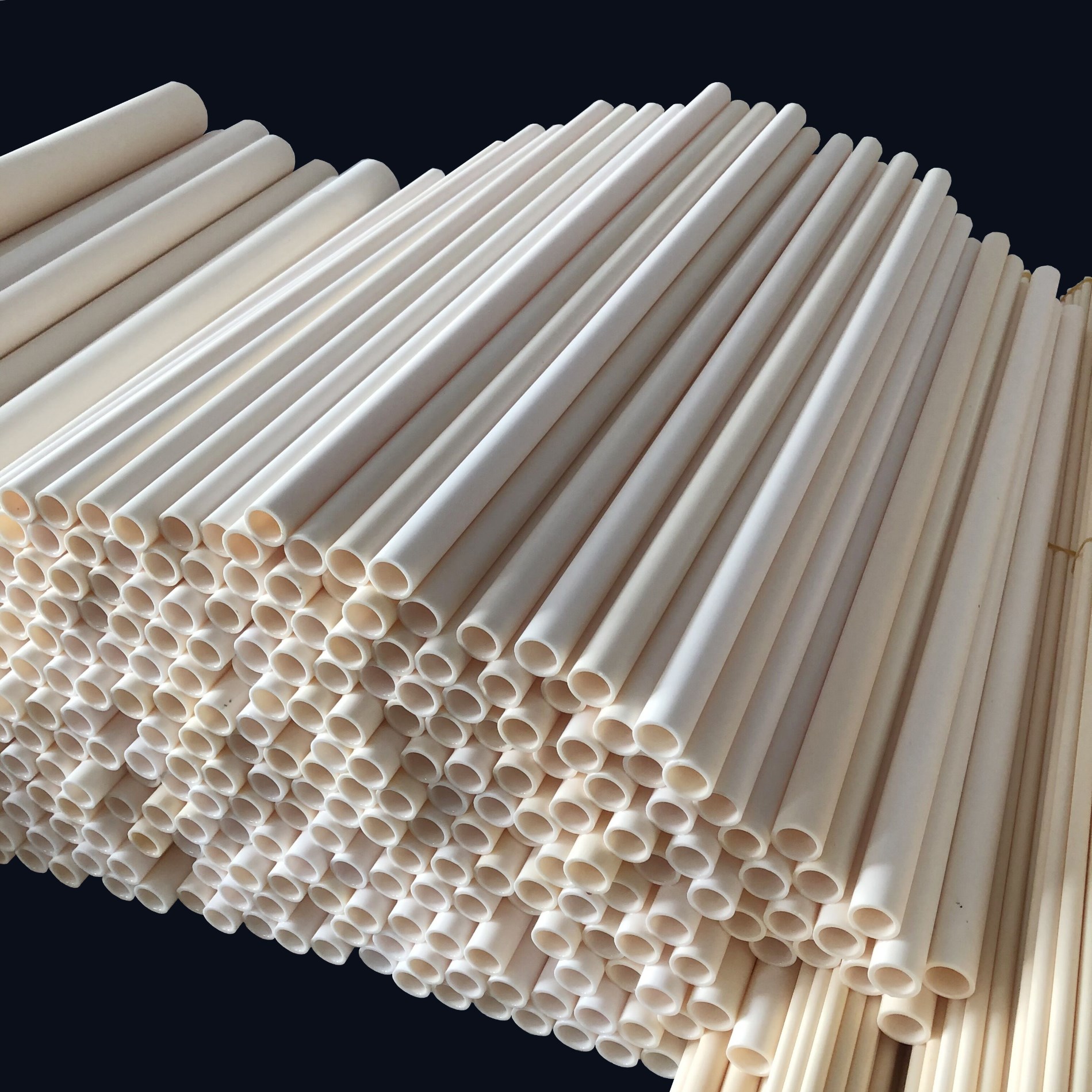

Alumina Furnace Pipe

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000-10,000/month(Looking for distributors)

1. Alumina Furnace Pipe are resistant to high temperatures, with long-term use at 1600 ℃ and short-term use at 1800 ℃ (Al2O3 ≥ 99%).

2. Alumina Furnace Pipe have chemical and corrosion resistance, making them suitable for use in chemical environments

3. Alumina Furnace Pipe are suitable for food processing, pharmaceuticals, and other industries that require non reactive ingredients.

4. The smooth and porous surface of Alumina Furnace Pipe makes them easy to clean, and long-term use can also maintain their appearance and function.

5. The wear resistance of Alumina Furnace Pipe extends their service life and reduces replacement and maintenance costs.

Alumina Furnace Pipe

My factory looking for distributors.

Advantages of Alumina Furnace Pipe

1. Alumina Furnace Pipe are resistant to high temperatures, with long-term use at 1600 ℃ and short-term use at 1800 ℃ (Al2O3 ≥ 99%).

2. Alumina Furnace Pipe have chemical and corrosion resistance, making them suitable for use in chemical environments

3. Alumina Furnace Pipe are suitable for food processing, pharmaceuticals, and other industries that require non reactive ingredients.

4. The smooth and porous surface of Alumina Furnace Pipe makes them easy to clean, and long-term use can also maintain their appearance and function.

5. The wear resistance of Alumina Furnace Pipe extends their service life and reduces replacement and maintenance costs.

Application of Alumina Furnace pipe

1. High mechanical strength: The Alumina Furnace Pipe and pipeline structure is precise, with extraordinary stability and sturdiness, and can be safely used in high-temperature furnace and kiln environments.

2. Best electrical insulation: Alumina Furnace Pipe have high electrical resistivity and excellent electrical insulation performance, ensuring the safety and reliability of electrical infrastructure.

3. Excellent optical performance: Alumina Furnace Pipe are the ideal choice for various applications in the optical industry.

4. Ion conductivity and industrial applications: Alumina Furnace Pipe have contributed to the advancement of semiconductor manufacturing and smart grid technology.

Instructions for use

1. When using alumina furnace tubes, it is best to control the heating and cooling rate to 5 degrees / minute, the slower the better.

2. Rapid cooling and rapid heating are one of the main reasons for the rupture of the alumina furnace tube. Our products have good resistance to quenching and heating.

3. Please keep the alumina furnace tube clean at all times, do not leave some samples in the alumina furnace tube, one side chemical reaction and cracking of the alumina furnace tube. It is recommended to put the test sample into the crucible and alumina furnace tube.

4. During lofting and sampling, it is best to be within 200 degrees and slowly push from the edge to the middle. High temperature sample delivery and sampling is also the main reason for corundum tube rupture.

5. Make sure to place mullite plugs on both sides of the alumina furnace tube to prevent heat radiation from damaging the silicone ring in the flange. The crucible should be placed in the middle of the alumina furnace tube.

Alumina Tube(open both ends)(slip casting) Specification Table

Number | SPEC: OD x ID |

LENGTH MM |

Number | SPEC: OD x ID |

LENGTH MM | ||

INCH | MM | INCH | MM | ||||

1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 |

≤1800 |

2 | 0.236x0.157 | 6x4 |

≤1300 | 33 | 1.181x0.827 | 30x21 | |

3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 | ||

4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 | ||

5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 | ||

6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 | ||

7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 | ||

8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 | ||

9 | 0.354x0.236 | 9x6 |

≤1600 | 40 | 1.654x1.339 | 42x34 | |

10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 | ||

11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 | ||

12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 | ||

13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 | ||

14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 | ||

15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 | ||

16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 | ||

17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 | ||

18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 | ||

19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 | ||

20 | 0.591x0.394 | 15x10 |

≤1800 | 51 | 2.750x2.500 | 69.9x63.5 | |

21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 | ||

22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 | ||

23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 | ||

24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 | ||

25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 |

≤1600 | |

26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 | ||

27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 | ||

28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 | ||

29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 |

≤1500 | |

30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 | ||

31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 | ||

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Factors to Consider When Choosing Alumina Furnace Tubes

When selecting alumina furnace tubes, several key factors should be taken into consideration to ensure optimal performance and longevity. These factors include:

Temperature Resistance: Alumina furnace tubes are known for their excellent heat resistance. Consider the maximum temperature the tubes will be exposed to in your application to ensure they can withstand these conditions without deformation or failure.

Chemical Compatibility: Determine the types of chemicals or gases that will come into contact with the furnace tubes. Alumina ceramics are generally resistant to many chemicals, but it's essential to confirm compatibility to avoid corrosion or degradation.

Mechanical Strength: Evaluate the mechanical stress the tubes will experience, including pressure and impact forces. Alumina ceramics exhibit high mechanical strength, but the specific design and thickness of the tubes may need to be tailored to the application's requirements.

Thermal Shock Resistance: Consider the frequency and severity of temperature fluctuations in your process. Alumina furnace tubes with superior thermal shock resistance can withstand rapid temperature changes without cracking or fracturing.

Dimensional Accuracy: Ensure that the dimensions and tolerances of the alumina furnace tubes align with your equipment and installation requirements. Customizable options may be available to meet specific size and shape needs.

Surface Finish: Depending on the application, the surface finish of the alumina furnace tubes may be crucial. A smooth surface can facilitate material flow or prevent buildup, while a textured surface may enhance thermal conductivity.

Cost and Longevity: Balance the initial cost of the alumina furnace tubes with their expected lifespan. High-quality tubes may have a higher upfront cost but can offer extended service life and reduced maintenance requirements, leading to overall cost savings.

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

Q1. Can alumina furnace tubes be reused?

Yes, alumina furnace tubes can indeed be reused after they've been used, as long as they remain undamaged and free from any contamination. It's essential to thoroughly clean and inspect them to confirm that they're still in good condition and suitable for future use.

Q2. Is it safe to use alumina furnace tubes in high-pressure applications?

Indeed, alumina furnace tubes are well-suited for high-pressure applications. Their exceptional mechanical strength, combined with resistance to thermal and chemical stresses, renders them capable of withstanding rigorous conditions.3. We have

Q3. Can alumina furnace tubes withstand rapid temperature changes?

Certainly, alumina furnace tubes demonstrate commendable thermal shock resistance, enabling them to endure rapid temperature fluctuations without experiencing cracks or fractures.

Q4. Can alumina furnace tubes be customized according to specific environments?

Indeed, numerous suppliers provide the option to customize alumina furnace tubes according to specific requirements. This customization may involve modifications to dimensions, form, and the incorporation of additional features, ensuring alignment with the precise needs of your application.

Q5. How long can alumina furnace tubes be used?The durability of alumina furnace tubes can differ based on factors like application conditions, operational temperatures, and maintenance procedures. Under suitable care and usage, these tubes can endure for multiple years, delivering consistent and dependable performance.

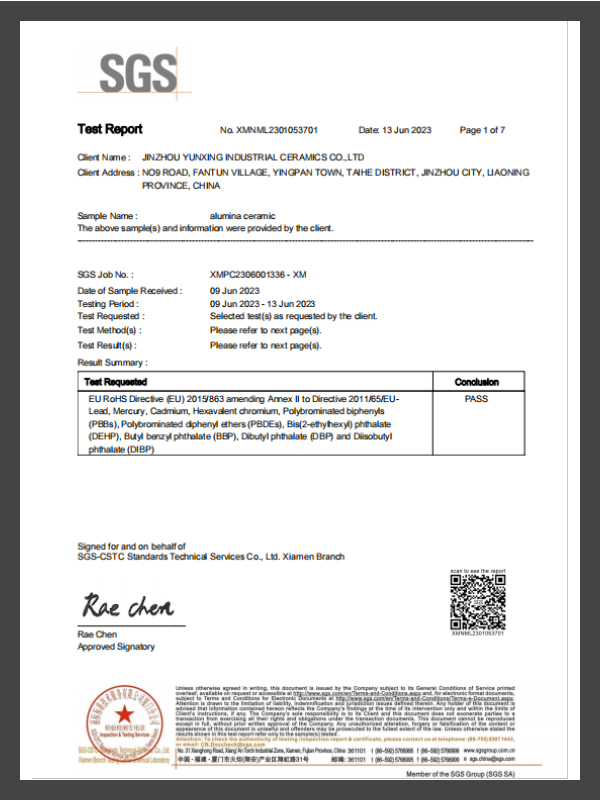

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.