Alumina Ceramic Plate

- YUNXING

- China Jinzhou

- 5-30 Days

- 2,000-3,000/month(Looking for distributors)

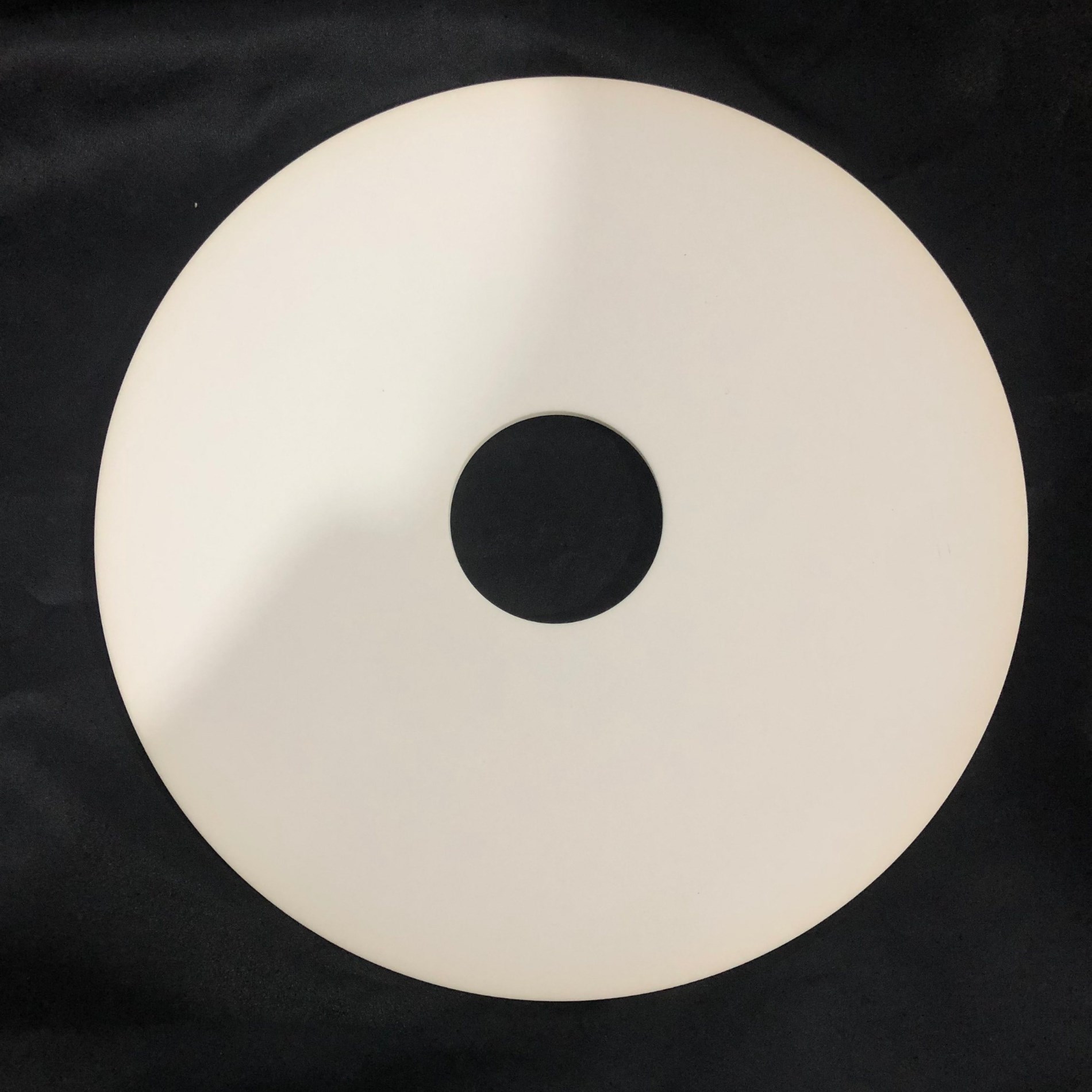

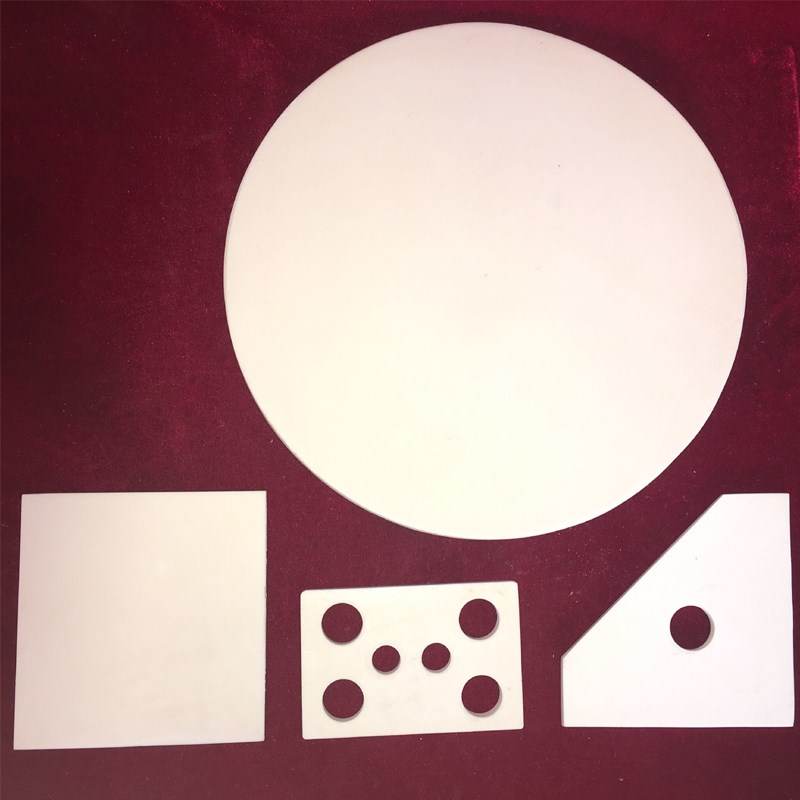

Alumina ceramic plate is also called wear-resistant alumina ceramic plate, high alumina ceramic plate, wear-resistant ceramic plate, alumina ceramic patch. Alumina ceramic plate is mainly made of AL2O3 as raw material, rare metal oxide as solvent and calcined at 1700℃.

Alumina Ceramic Plate

My factory looking for distributors.

Alumina ceramic plate is also called wear-resistant alumina ceramic plate, high alumina ceramic plate, wear-resistant ceramic plate, alumina ceramic patch. Alumina ceramic plate is mainly made of AL2O3 as raw material, rare metal oxide as solvent and calcined at 1700℃.

Advantages of alumina ceramic plate

1.The Alumina Ceramic Plates have been meticulously crafted to exhibit exceptional hardness and durability.

2.The Alumina Ceramic Plates offer excellent electrical insulation properties.

3.The alumina ceramic plates boast high density and rigidity.

4.Understanding the needs and preferences of our esteemed customers, we have crafted the Alumina Ceramic Plates to meet their highest standards.

5.Our Alumina Ceramic Plates are incredibly versatile, offering endless possibilities for various applications.

Application of alumina ceramic plate

The alumina ceramic plate has become the protective film of the machine. The addition of alumina ceramic plate on the machine is not only high temperature resistant, but also can effectively prevent the machine from slipping, reduce the friction and impact in the machine, keep the machine long-term production without damage, reduce maintenance, and save The production cost effectively prolongs the service life of the machine. Of course, the important point is that the alumina ceramic plate is environmentally friendly, which can effectively reduce energy consumption and is conducive to the long-term development of the industry.

Recommended products:

Ceramic beads

2 bores round ceramic beads used in thermocouple could satisfy the turning,gyration,warping etc measurement requirement in complex conditions.

Ceramic rods

With high density&refractoriness,good corrosion resistence,mechanical capacity etc properties,ceramic rods are widely used in chemical fiber,

textile and chemical etc industries.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

What is the difference between ceramic and alumina?

Ceramics are non-metallic, inorganic materials that are typically composed of a combination of metallic and non-metallic elements. Alumina is a type of ceramic oxide, specifically an oxide of aluminum. It is widely used in various applications due to its excellent mechanical, thermal, and electrical properties.

What is alumina ceramic used for?

Everything You Need to Know about Alumina Ceramics

Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves. Aluminum oxide ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

Is alumina ceramic hard?

Alumina is a very hard ceramic that is excellent at resisting abrasion and is ideal for wear-resistant inserts or products.

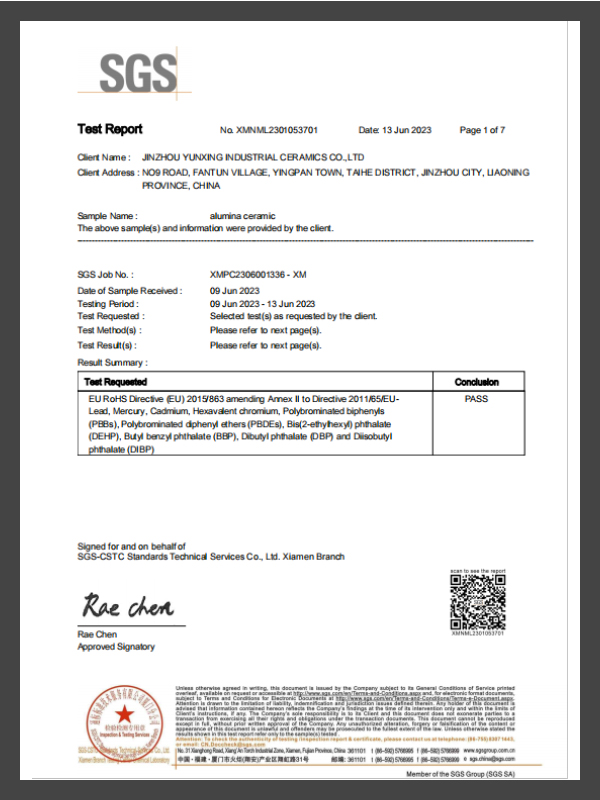

Certificate

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.