Selection of Crucible in Synchronous Thermal Analyzer

Selection of Crucible in Synchronous Thermal Analyzer

Synchronous thermal analyzer is to study the physical and chemical changes of materials during heating through the endothermic and exothermic behaviors and the weight changes of materials during heating. It is usually one of the basic equipments in material science. General synchronous thermal analyzer consists of heating system, temperature control system, signal amplification system, differential thermal system and recording system.

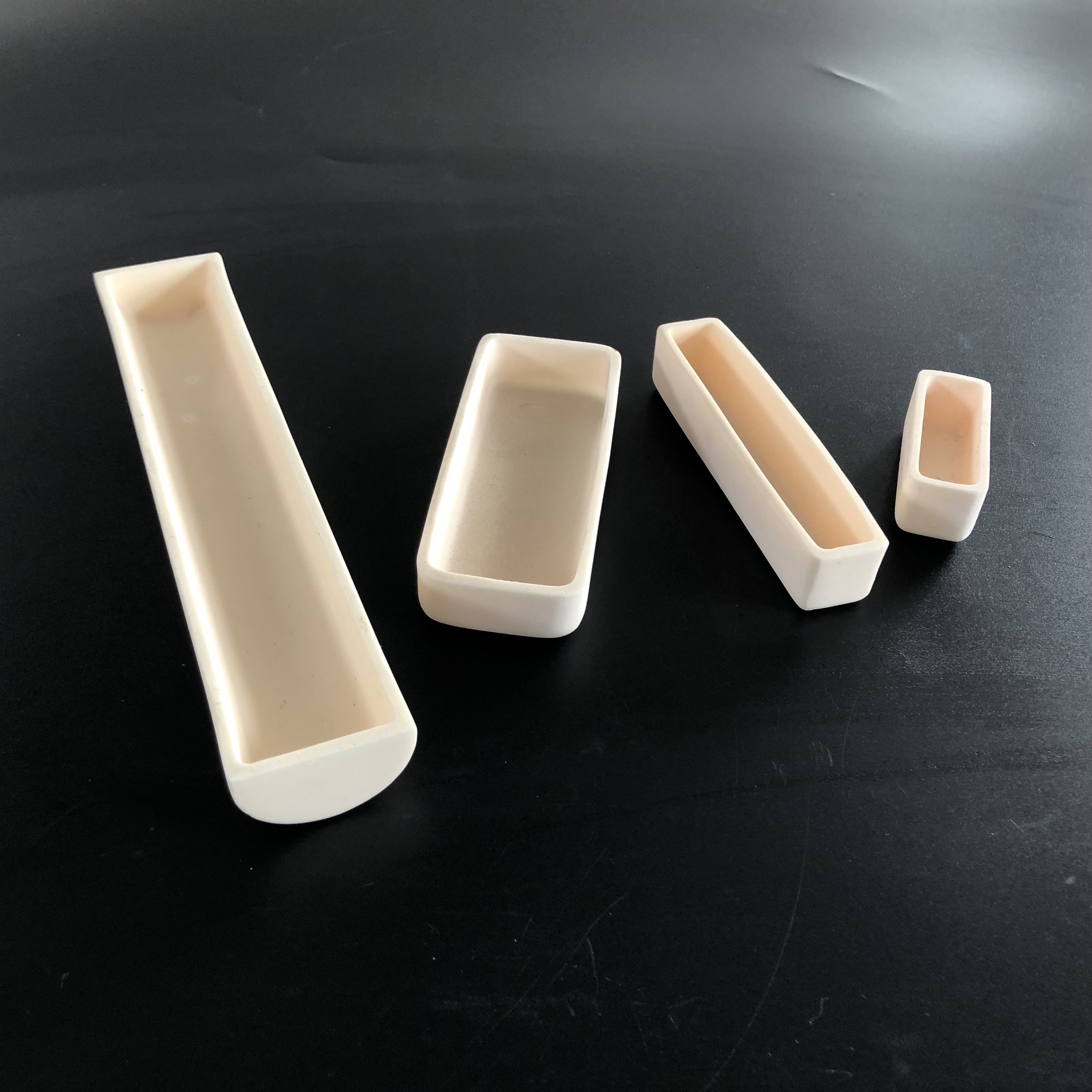

1. Aluminium oxide crucible (Alumina ceramic crucible). The crucible is commonly used in TGA experiments. It is relatively stable to most samples and does not react with the samples. In the range of room temperature to 1650℃, the aluminum oxide crucible has no thermal reaction. The melting point of the aluminum oxide crucible exceeds 1700℃, which can be reused, but the cleaning process is somewhat troublesome.

2. Platinum crucible. Platinum crucibles are also reusable crucibles. Platinum crucible has good thermal conductivity. Compared with ceramic crucible, using platinum crucible in synchronous thermal analyzer can obtain better synchronous DSC test results. However, it should be noted that platinum may become a catalyst for some samples, so careful analysis should be carried out before use. The melting point of platinum crucible is 1770℃. During the high temperature test, platinum crucible may form a eutectic point with some metals and compounds, and the melting point of the crucible decreases, resulting in the crucible sticking to the sensor. To solve the problem of alloy formation between the metal sample and the platinum crucible, a thin layer of alumina powder can be added to the bottom of the platinum crucible, and then the metal sample is placed on the alumina powder.

3. Aluminum crucible. The use of aluminum crucibles in TGA experiments can only be carried out at low temperature, and the high temperature cannot exceed 600℃, because the melting point of aluminum crucibles is 600℃. The aluminum crucible has good heat conduction, and the crucible arm and bottom are thin, so the synchronous DSC signal tested is good. Moreover, the aluminum crucible can be sealed well. Therefore, aluminum crucibles can be selected for testing DSC results with synchronous thermal analyzer, and the testing temperature is lower than 600℃.

4. Sapphire crucible. Sapphire crucibles are also made of aluminum oxide and can be reused. Sapphire crucibles have stronger stability and barrier properties, and are especially suitable for testing refractory metals, such as steel, that easily decompose and penetrate ordinary alumina crucibles at high temperatures. While ordinary ceramic crucibles are also made of aluminum oxide, they have a porous structure and are easily permeable to melt. The melting point of sapphire crucible also exceeds 1700℃.