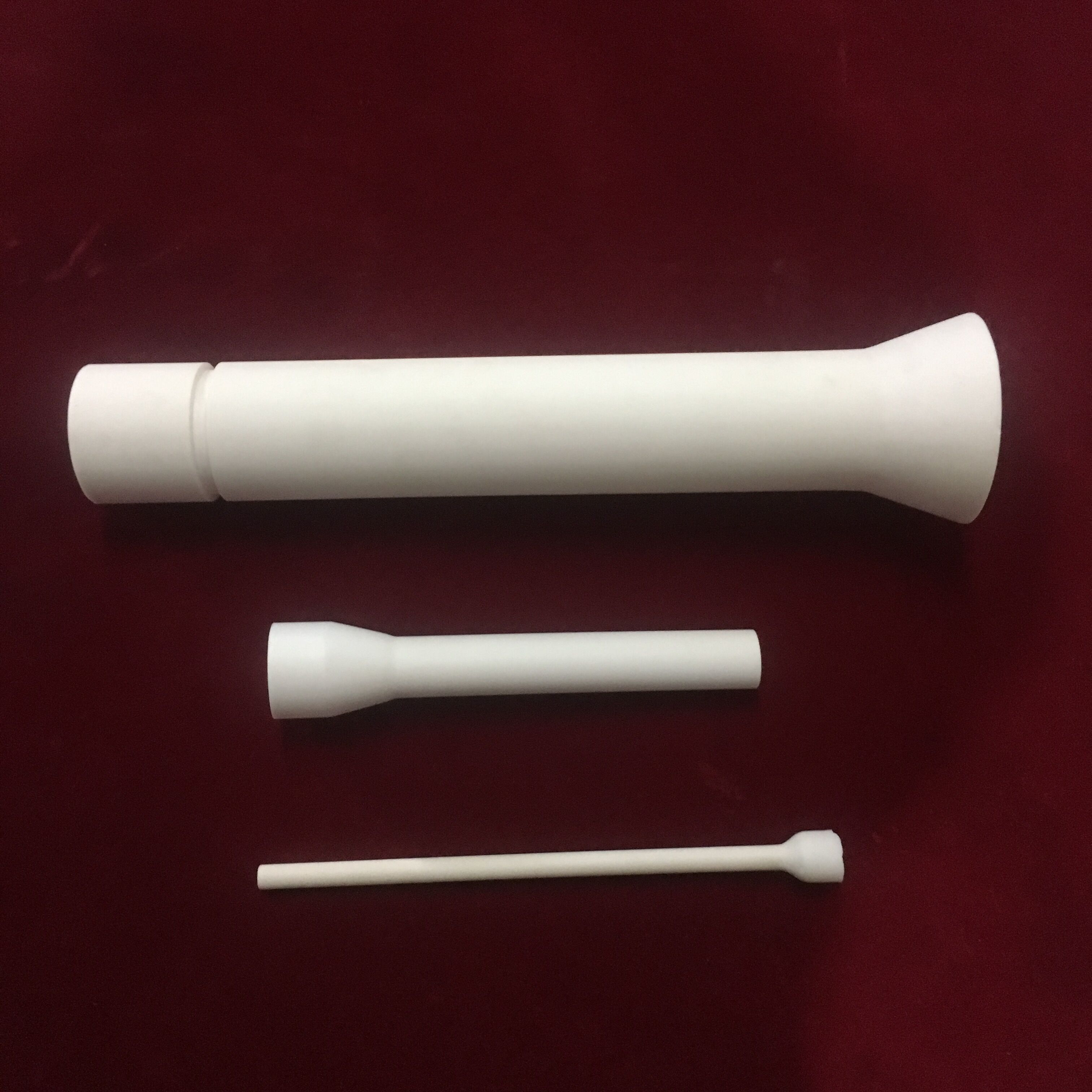

Corundum castable or corundum mullite castable

Corundum castable or corundum mullite castable

Corundum castable and corundum mullite castable are common amorphous refractory materials, which is better, corundum castable or corundum mullite castable, which can be used for lining of various high-temperature industrial kilns? The difference between corundum castable and corundum mullite castable needs to be known before knowing which is better.

First of all, we can distinguish from the raw materials and properties. The corundum contained in the corundum refractory castable is a cubic crystal system, and its crystal form is generally short columnar.

The corundum itself also has high thermal conductivity and electrical insulation performance, excellent chemical stability and resistance to reducing agent. The corundum castable produced has high wear resistance and high temperature resistance.

The mullite contained in corundum-mullite refractory castable is relatively small in nature when it is prepared, and the mullite raw materials used in industry are all artificially synthesized, which has the advantages of high purity, high density, good structure, low creep rate, small thermal expansion, good thermal shock resistance and strong chemical erosion resistance.

Corundum-mullite castable is widely used in refractory materials and other industries. The corundum-mullite castable uses high-quality refractory raw materials, and the prepared refractory castable has good thermal shock resistance.

Secondly, we can see from the testing indexes of refractory castables that the aluminum content of corundum castables is above 90%, the aluminum content of corundum mullite castables is below 90%, the aluminum content of corundum castables is higher than that of corundum mullite castables, the aluminum content of corundum castables is high, the price is higher than that of corundum mullite castables, and the application effect of corundum castables is better.

From the perspective of refractory industry, the principle of refractory used for lining of high-temperature kilns is that corundum-mullite castable can meet the requirements according to the operating environment of the kilns, the selected use temperature, performance, service life and cost of refractory, and corundum castable need not be selected.